180 degree two side metal joint(for connecting joint) lean pipe system component

Product introduction

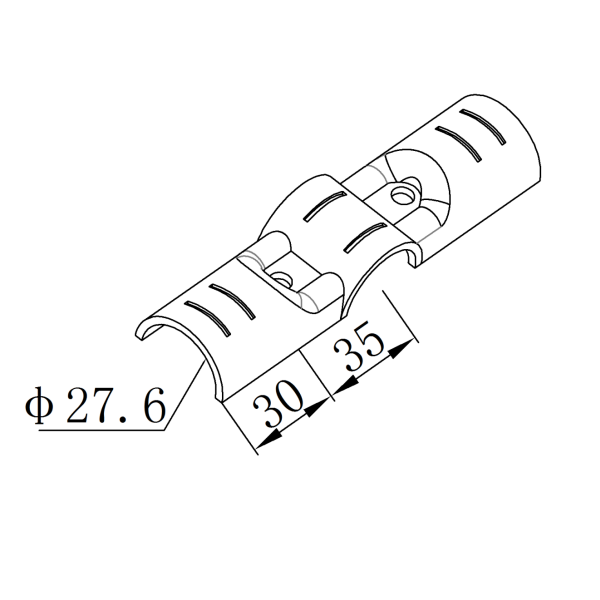

The thickness of 180 degree two side metal joint(for connecting joint) is 2.5mm, which can ensure that it has a strong bearing capacity. Screw holes are also reserved on the surface of the product to facilitate the user to drive screws for fixation. Tighten the pipe clamp to the pipe. After the joint is grinded, the burr on the joint surface can be greatly reduced or even completely cleared, effectively reducing the risk of injury to workers in the workplace. The surface of the joint will be punched with stripes or dots during stamping, so as to better increase the friction between the joint and the pipe and make the whole structure more firm. The surface treatment of the joint adopts electroplating, which can effectively prevent its rusting and prolong the service life of the joint.

Features

1. Two equipotential lines on both sides of the product, so the installation position of the tube can be known when using. Auxiliary user installation.

2.The thickness of the product is up to 2.5, 25% thicker than most products, with stronger performance and higher bearing capacity.

3. Holes are reserved on the surface of the product, and self-tapping screws can be inserted later to better fix the pipe.

4. Products can be customized with logos and marked with models according to different needs of customers.

Application

The use of 180 degree two side metal joint (for connecting joint) is very simple. Only two pairs of M6 * 25 screw and nut are required to connect the three lean pipes. It is used to form a cross structure with three lean pipes. The 180 degree two side metal joint(for connecting joint) is commonly used to secure onto a T-type direct joint. Moreover, the connection between the connector and the lean pipe conforms to human mechanics. Only one M6 hexagonal wrench can complete the installation process. External corner joint is often used in various material racks and turnover vehicles. It is the most commonly used joint in the lean pipe system.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | W-4A |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Technics | stamping |

| Thickness | 2.5mm |

| Weight | 0.1kg/pcs |

| Material | Steel |

| Size | For 28mm pipe |

| Color | Black, Zinc, Nickel, Chrome |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 20000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, etc. |

| Transportation | Ocean |

| Packing | 200 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.