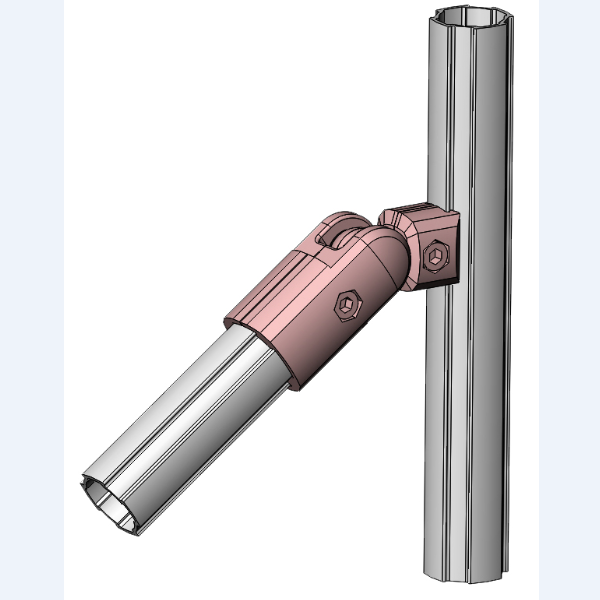

2022 wholesale price Karakuri Automation - 180 degree external rotary aluminum joint Karakuri System Connector – WJ-LEAN

2022 wholesale price Karakuri Automation - 180 degree external rotary aluminum joint Karakuri System Connector – WJ-LEAN Detail:

Product introduction

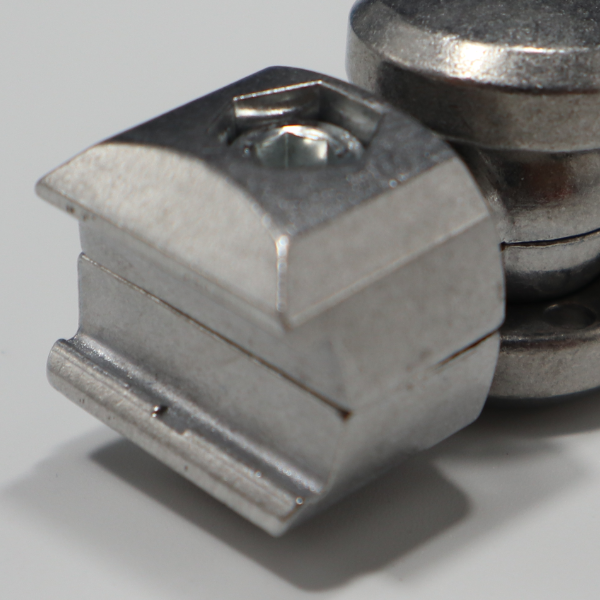

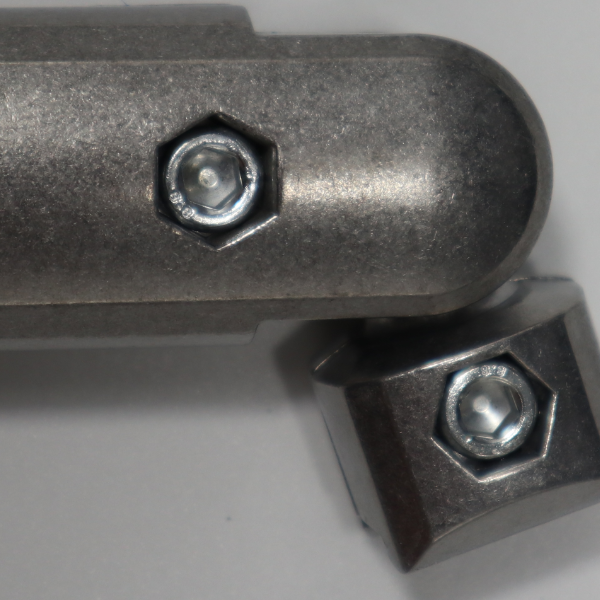

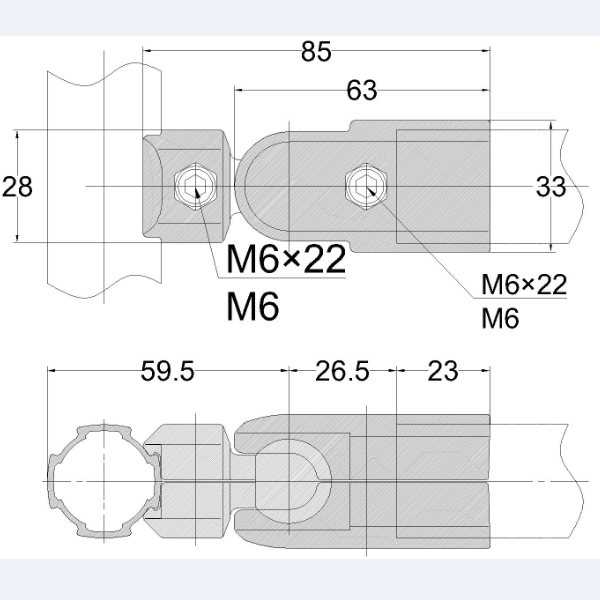

WJ-LEAN’s third-generation lean tube aluminum joint are made of 6063T5 aluminum alloy raw materials, which can ensure the products have good corrosion resistance and oxidation resistance. 6063T5 aluminum alloy also has the advantages of good plasticity, moderate heat treatment strength and good welding performance. Our corner joint naturally also have this series of advantages. WJ LEAN’s aluminum joint is grinded, which can ensure that there is no huge friction when the joint rotates.

Features

1. We use international standard size, can be used in any international standard parts.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, and the overall system is beautiful and reasonable after assembly.

4. Product diversification design, DIY customized production, can meet the needs of different enterprises.

Application

This aluminum joint can connect two aluminum tubes and make them rotate within 180 degrees. It can realize the turning connection in the aluminum tube rack. These products can be widely used in household, automobile, electronics, chemical industry, commercial logistics, flexible storage equipment, pharmacy, machine manufacturing. The external rotary joints are commonly used in aluminum tube workbench, fluent shelf, first in first out(FIFO) racking.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Square |

| Alloy Or Not | Is Alloy |

| Model Number | 28J-3 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Temper | T3-T8 |

| Surface treatment | Anodized |

| Weight | 0.12kg/pcs |

| Material | 6063T5 aluminum alloy |

| Size | For 28mm aluminum pipe |

| Color | Sliver |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 10000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 150 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for 2022 wholesale price Karakuri Automation - 180 degree external rotary aluminum joint Karakuri System Connector – WJ-LEAN , The product will supply to all over the world, such as: Estonia, Botswana, Malaysia, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.