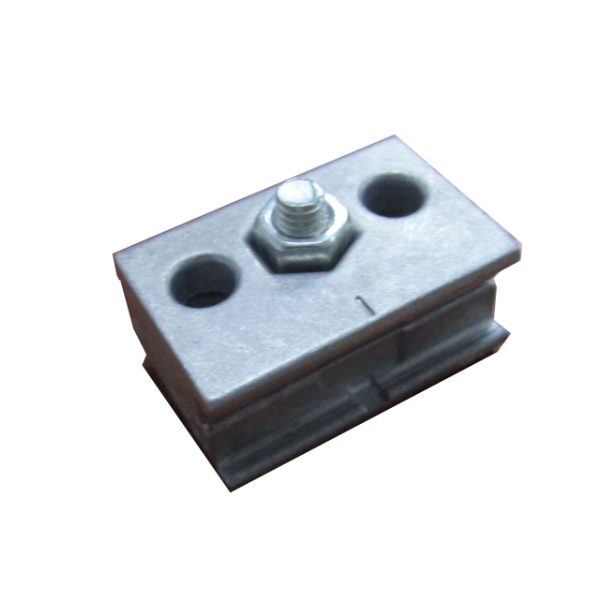

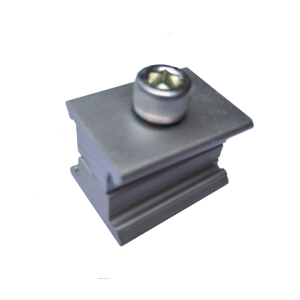

Aluminum alloy single side accessory Karakuri accessory

Product introduction

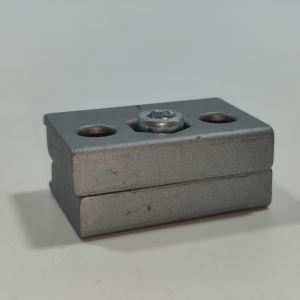

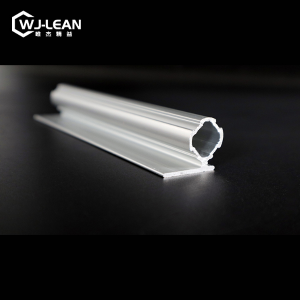

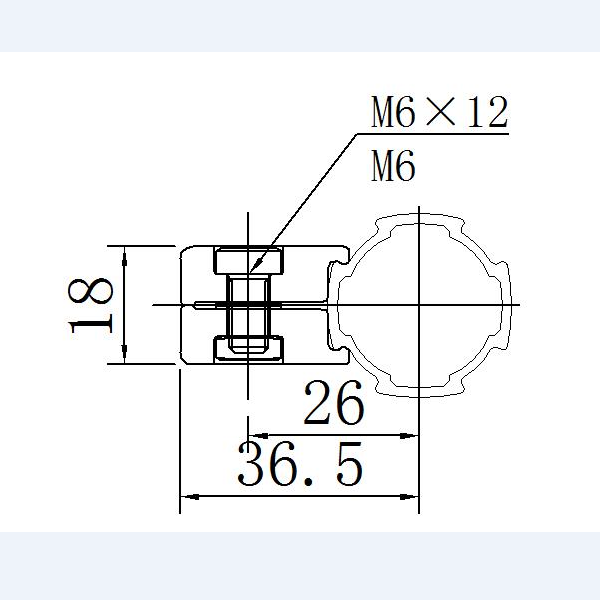

The multi-functional single side aluminum alloy joint fitting 28AC-3 has two M6 mounting holes, which is convenient for users to connect other accessories with screws. One groove can be fixed on the aluminum pipe by tightening screws. Therefore, this fitting can also act as a fixed translation sliding sleeve on the aluminum pipe rack. The weight of the product is only 0.06kg, and the surface is anodized. Long service life and not easy to deform.

Features

1. The weight of aluminum alloy is about 1/3 of that of metal pipe. The design is light and stable with excellent corrosion resistance.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, and the overall system is beautiful and reasonable after assembly.

4. Product diversification design, DIY customized production, can meet the needs of different enterprises.

Application

28AC-3 has two M6 mounting holes. The mounting holes are embedded with nuts and galvanized. Only M6 screws are required to complete the installation. This fitting can also be used on 43 series aluminum tubes.Because the product can only be fixed in one position after tightening, it can be regarded as a fixed device for some translational sliding sleeves.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Square |

| Alloy Or Not | Is Alloy |

| Model Number | 28AC-3 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Temper | T3-T8 |

| Surface treatment | Anodized |

| Weight | 0.06kg/pcs |

| Material | Aluminum |

| Size | For 28mm aluminum pipe |

| Color | Sliver |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 10000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 300 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

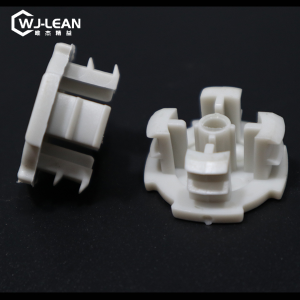

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Brand Story

In 2005, Wu Jun, who had long heard that Japan had advanced production technology, came to a Japanese company in Dongguan to study manufacturing.When he came to this company again in 2008, he found that a production line of the Japanese company at that time only took 2 days from assembly to use.Since then, I have a bold idea to introduce this advanced production line into China and carry it forward, and continuously improve the material technology.Later, in order to attract business, he simply sold all the spare parts of this lean production to the world. Five years later, his "Wu Jun" brand spare parts have been sold all over the world.In order to make local customers more satisfied, he personally released the market and communicated with many customers around the world in depth. But due to external accent problems,Locals always call "Wu Jun" a pronunciation similar to "weijie", and the Weijie brand was born. In 2020, the company's brand will be upgraded and its name will be officially changed to "WJ-lean". We use highly adjustable mechanisms and actuators as well as other necessary solutions to deliver fully functional products.The company has all industry product systems, including but not limited to MB industrial aluminum profile assembly system, lean production system, linear module system, workbench system and small elevator platform system.Provide advanced solutions for lean production automation, ergonomics and future intelligent manufacturing.