Excellent quality Track Roller - T-type direct metal joint lean pipe system component – WJ-LEAN

Excellent quality Track Roller - T-type direct metal joint lean pipe system component – WJ-LEAN Detail:

Product introduction

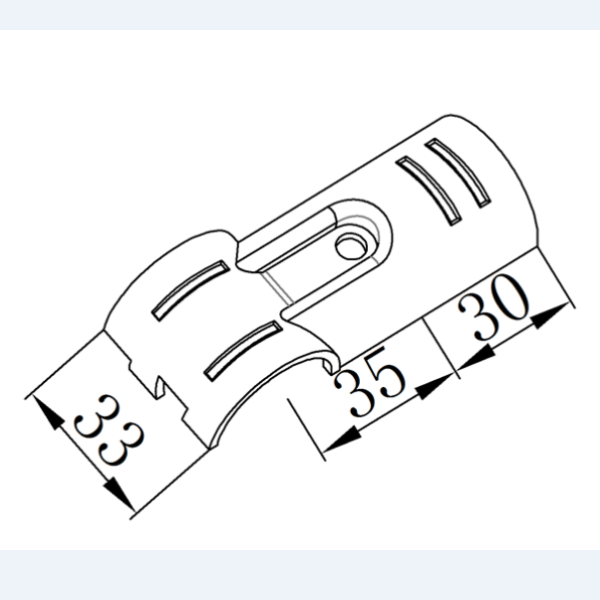

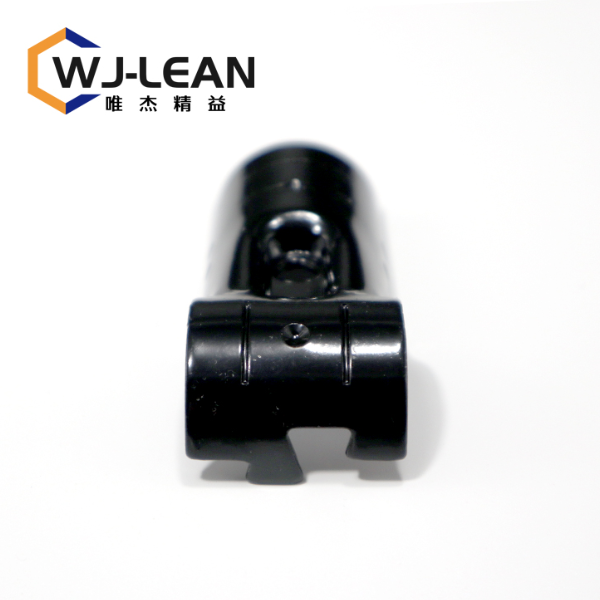

The thickness of T-type direct joint is 2.5mm, which can ensure that it has a strong bearing capacity. Screw holes are also reserved on the surface of the product to facilitate the user to drive screws for fixation. The equipotential line is stamped on both sides of the product to facilitate the user to measure the connection depth between the joint and the pipe during use. The surface treatment of the joint adopts electroplating, which can effectively prevent its rusting and prolong the service life of the joint.

Features

1. Two equipotential lines on both sides of the product, so the installation position of the tube can be known when using. Auxiliary user installation.

2.The thickness of the product is up to 2.5, 25% thicker than most products, with stronger performance and higher bearing capacity.

3. Holes are reserved on the surface of the product, and self-tapping screws can be inserted later to better fix the pipe.

4. Products can be customized with logos and marked with models according to different needs of customers.

Application

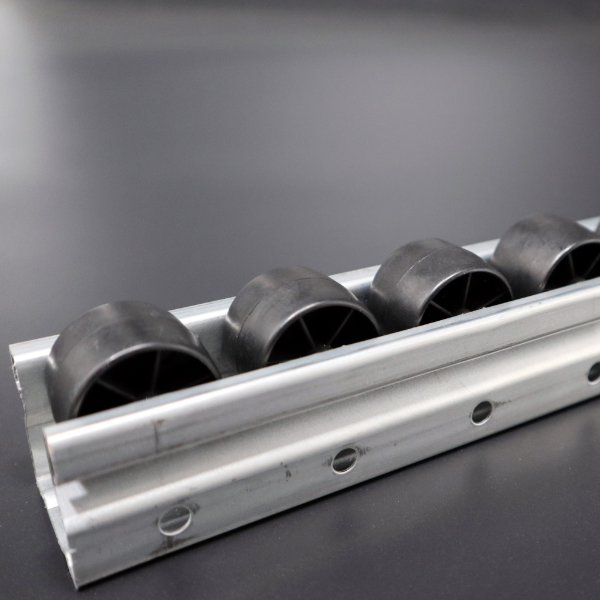

The use of T-type direct joint is very simple. Only two pieces of connectors and a pair of M6 * 25 screw and nut are required to connect the two lean pipes in T-shape. The connection may form a 90 degree structure at the edge of the tube. You can even use T-type direct joints and lean pipes to build a shelf. T-type direct joint is often used in various material racks and turnover vehicles. It is the most commonly used joint in the lean pipe system.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | W-1 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Wheel material | stamping |

| Thickness | 2.5mm |

| Weight | 0.07kg/pcs |

| Frame material | Steel |

| Size | For 28mm pipe |

| Color | Black, Zinc, Nickel, Chrome |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 300 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Excellent quality Track Roller - T-type direct metal joint lean pipe system component – WJ-LEAN , The product will supply to all over the world, such as: Angola, Sydney, Puerto Rico, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.