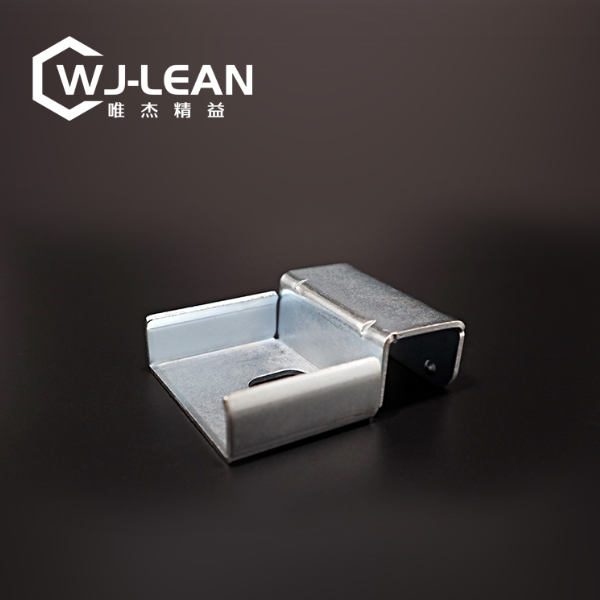

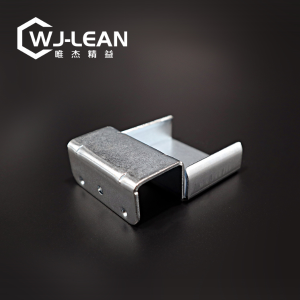

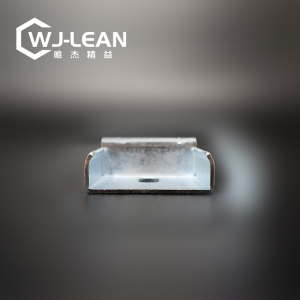

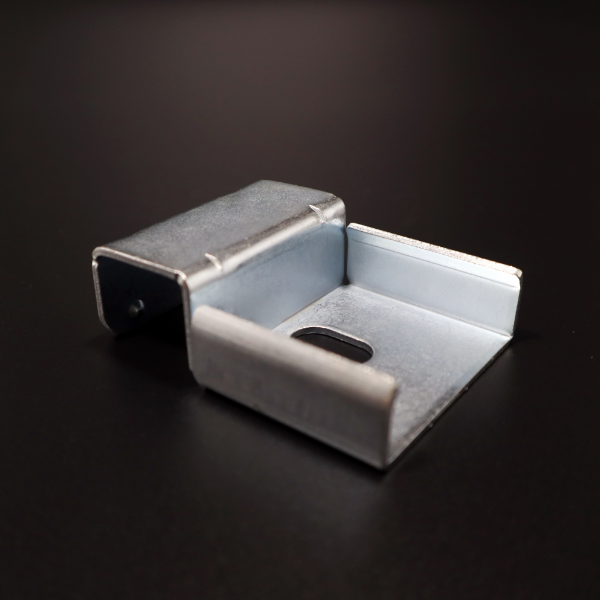

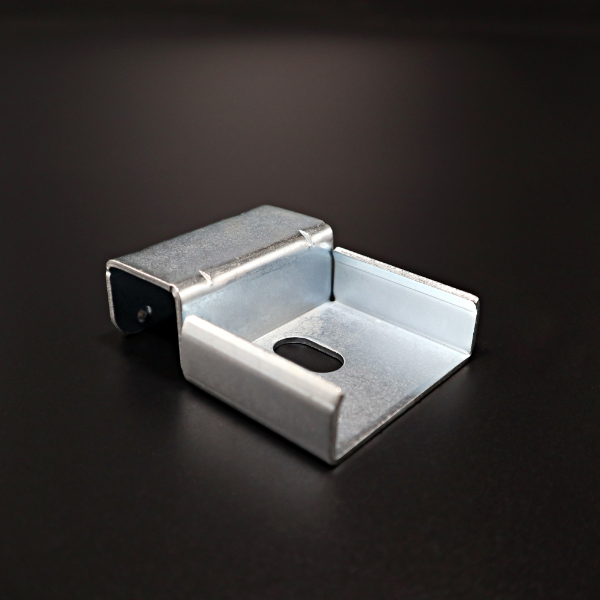

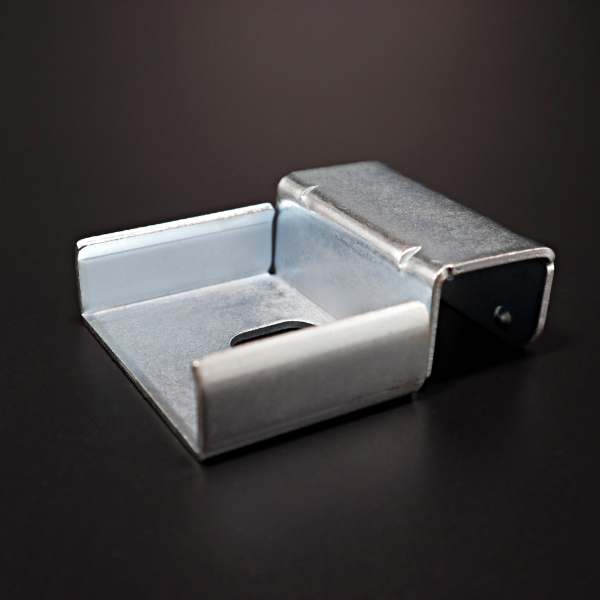

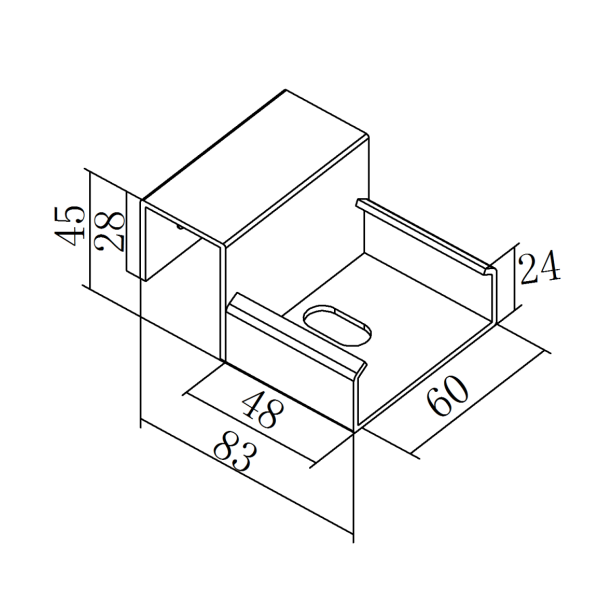

High Strength galvanized type 60 steel flat roller track joint flow racking accessory

Product introduction

The connector matched with the roller track has projections on the inner wall of the pipe, which can better fix the roller track connector on the pipe. The joint is stamped from cold rolled steel and weighs only 0.175kg. However, it has high hardness and excellent bearing capacity and is not easy to deform after long-term use. Its surface is galvanized to make it smooth and easy to access when installing the slide rail. At the same time, the service life of the product has been extended.

Features

1.The surface has been galvanized, nickel plated and other electroplating treatments, the products will have a fine exterior, rust proof and corrosion-resistant.

2.Easy assembly, screws are not required in the whole installation process.

3. The roller track joint is made of high-strength material, which has long service life, is not easy to deform, and can be reused.

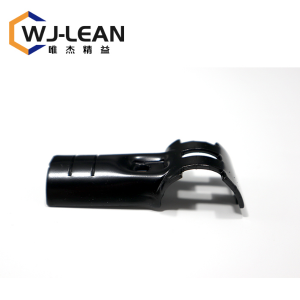

4.Various styles, can meet the needs of different situations.

Application

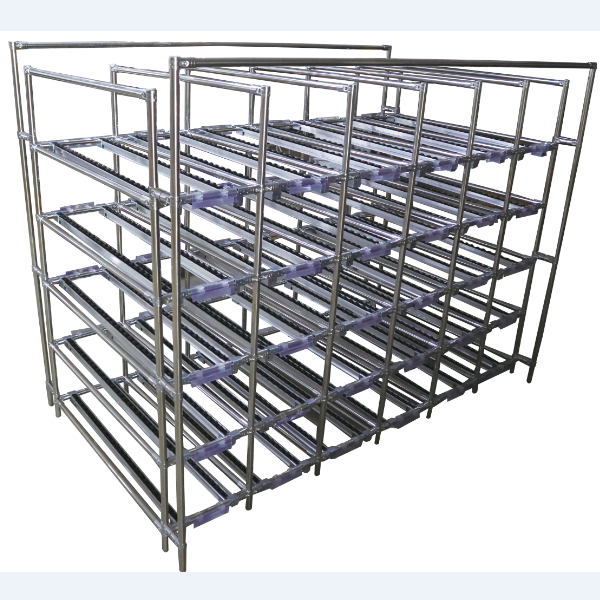

This type 60 flat roller track joint is usually connected to both ends of the roller track to assist the connection between the roller track and the lean pipe. Although the type 60 flat roller track joint is not as common as the type 40 flat roller track joint, it is still an important accessory for heavy duty flow racking. The roller track flat joint can make the goods slide on the slide rail without obstacles. It can effectively improve the work efficiency. It is an important part of the enterprise's internal logistics conveyor belt. At the same time, the roller track on the material turnover vehicle also needs its assistance to be better used.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | RTJ-2060C-A |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Technics | stamping |

| Groove width | 60mm |

| Weight | 0.175kg/pcs |

| Material | Steel |

| Size | For Roller Track |

| Color | Zinc, Nickel, Chrome |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 50 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.