Hot New Products Karakuri System - Aluminum inlay joint Karakuri system accessory – WJ-LEAN

Hot New Products Karakuri System - Aluminum inlay joint Karakuri system accessory – WJ-LEAN Detail:

Product introduction

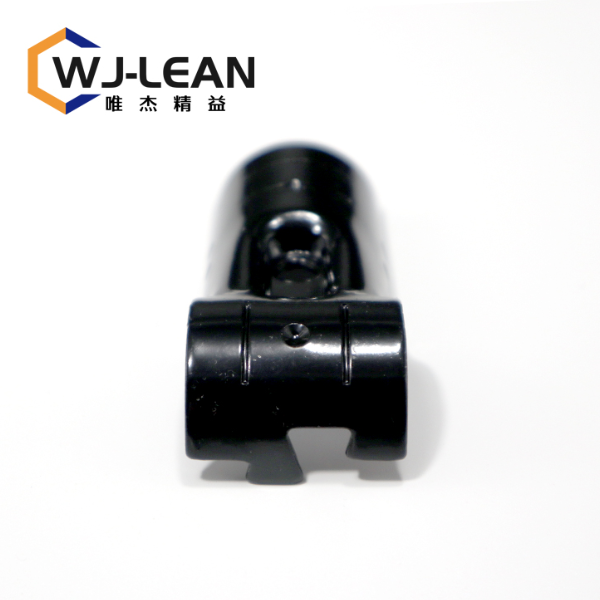

The weight of aluminum alloy accessory 28AC-1 is only 0.03 kg, which is very light. There are T-shaped grooves at the upper and lower ends to facilitate the user to connect the slider and other aluminum alloy accessories. At the same time, there are M6 screw holes inside the T-shaped groove, which can be used to drive screws to make the 28AC-1 accessory and the aluminum pipe more tightly. Similarly, 28AC-1 can be connected with wood plate through M6 screw hole, which is a key part of aluminum tube workbench.

Features

1. The weight of aluminum alloy is about 1/3 of that of metal pipe. The design is light and stable with excellent corrosion resistance.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

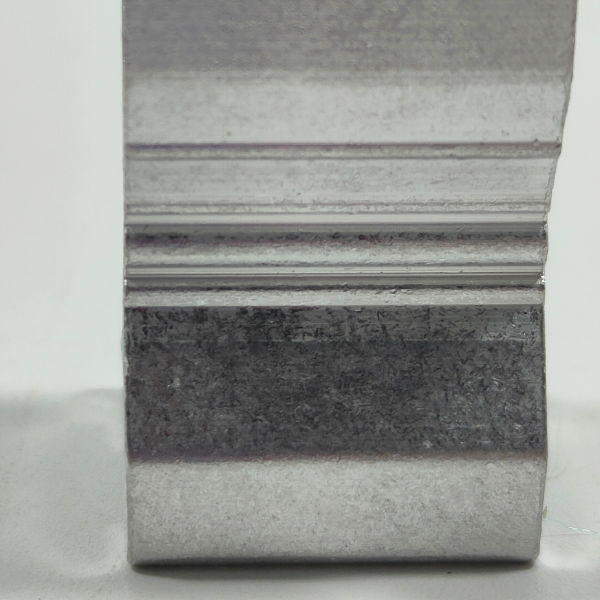

3. Aluminum alloy surface is oxidized, and the overall system is beautiful and reasonable after assembly.

4. Product diversification design, DIY customized production, can meet the needs of different enterprises.

Application

This inlay joint is usually used to fix the connection of the worktable board or other auxiliary parts. It can also be clamped and fixed with the aluminum pipe by driving the screw into the screw hole. The T-grooves on both sides also support other external or internal joints, such as aluminum alloy fittings such as sliders and pulleys with sliders.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Square |

| Alloy Or Not | Is Alloy |

| Model Number | 28AC-1 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Temper | T3-T8 |

| Surface treatment | Anodized |

| Weight | 0.03kg/pcs |

| Material | Aluminum |

| Size | For 28mm aluminum pipe |

| Color | Sliver |

Other information

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 10000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 400 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined rate competiveness and good quality advantageous at the same time for Hot New Products Karakuri System - Aluminum inlay joint Karakuri system accessory – WJ-LEAN , The product will supply to all over the world, such as: Bolivia, Mauritius, Serbia, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.