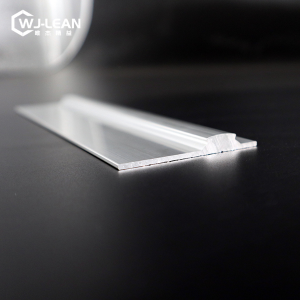

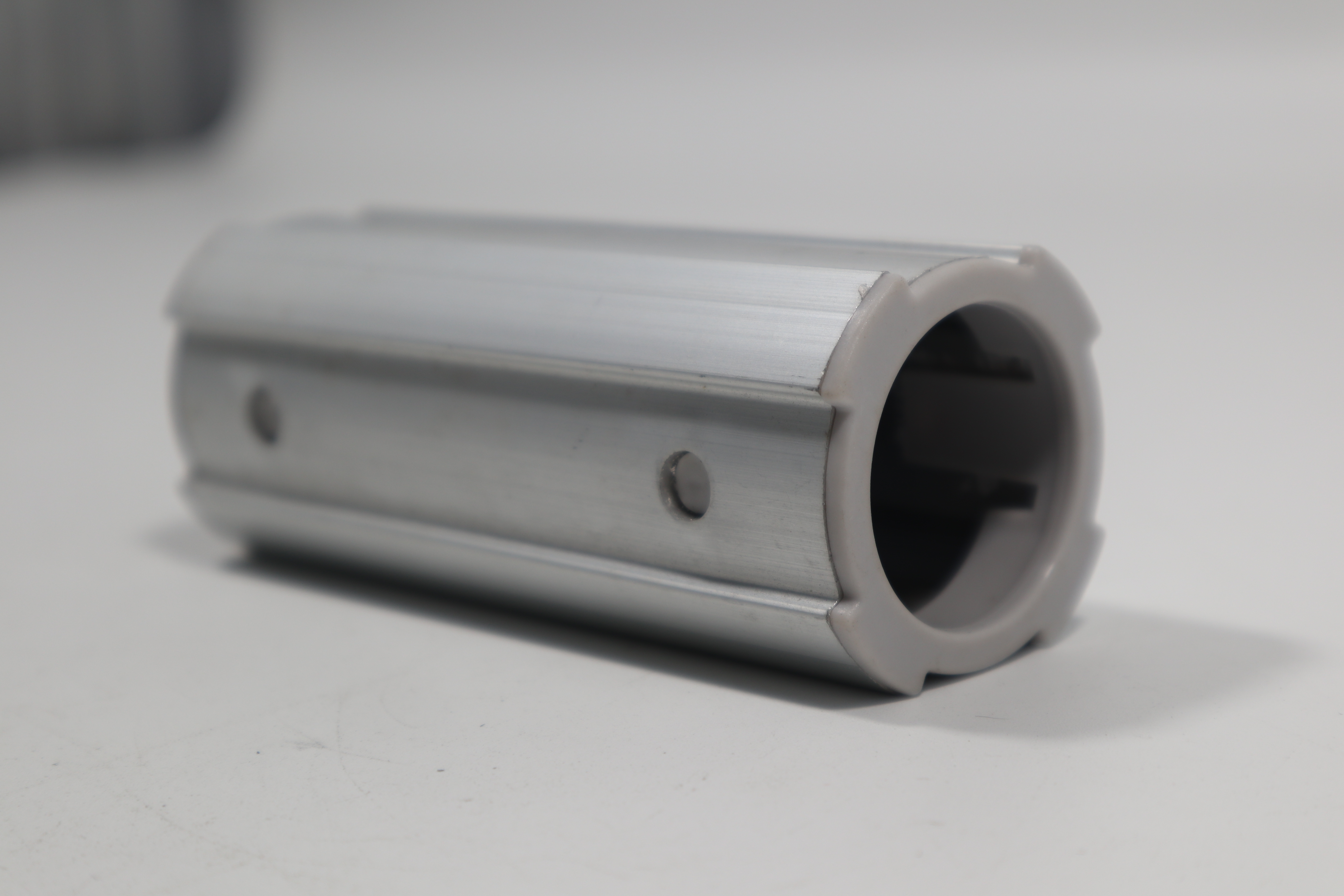

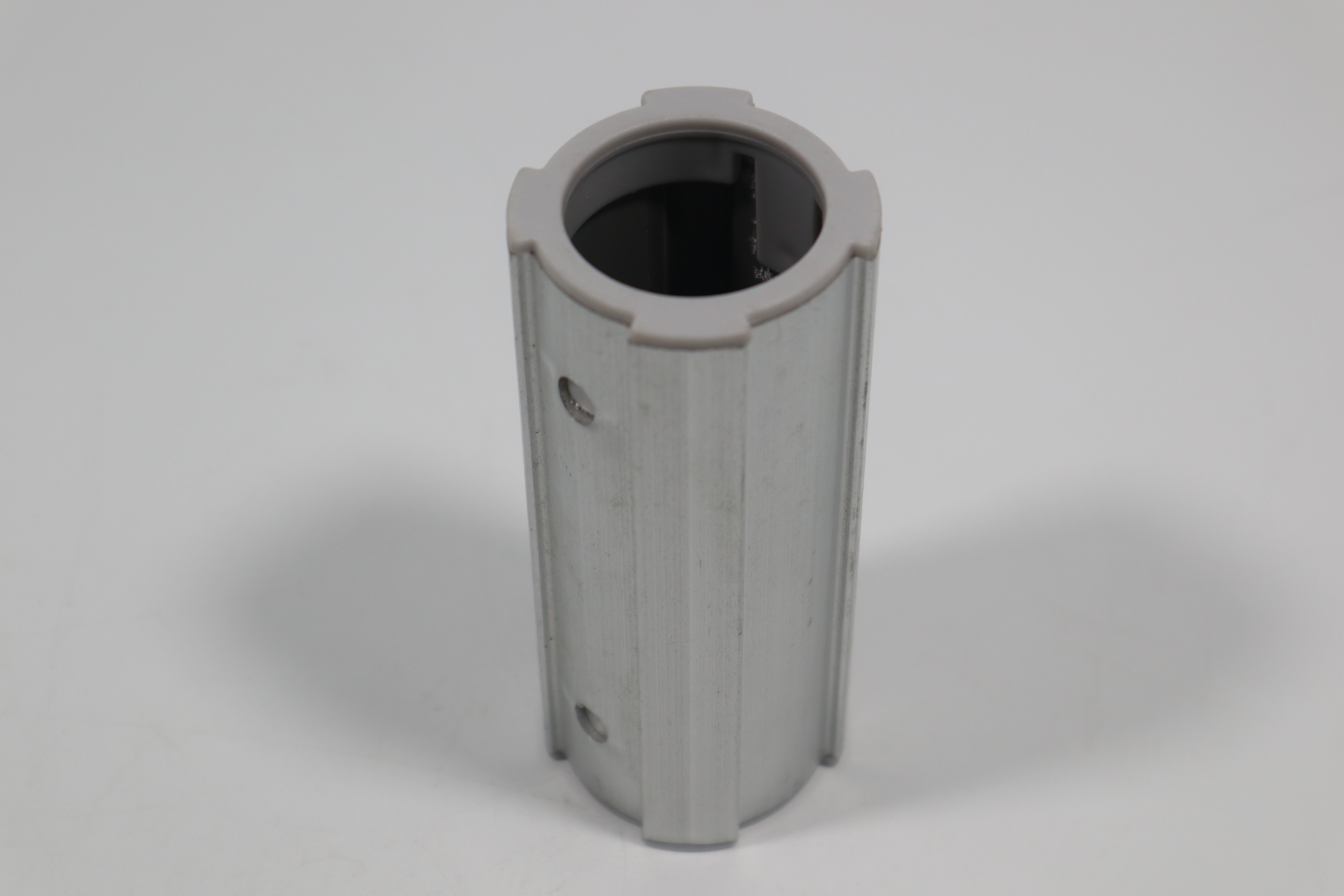

Karakuri System Linear Sliding Aluminum Mechanism

Product introduction

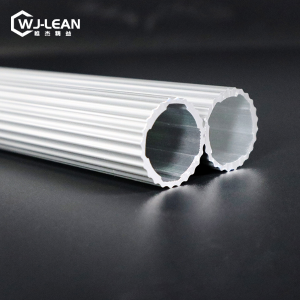

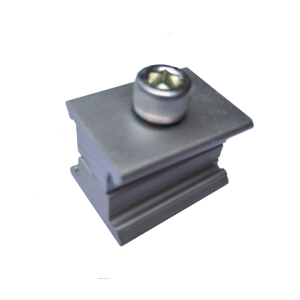

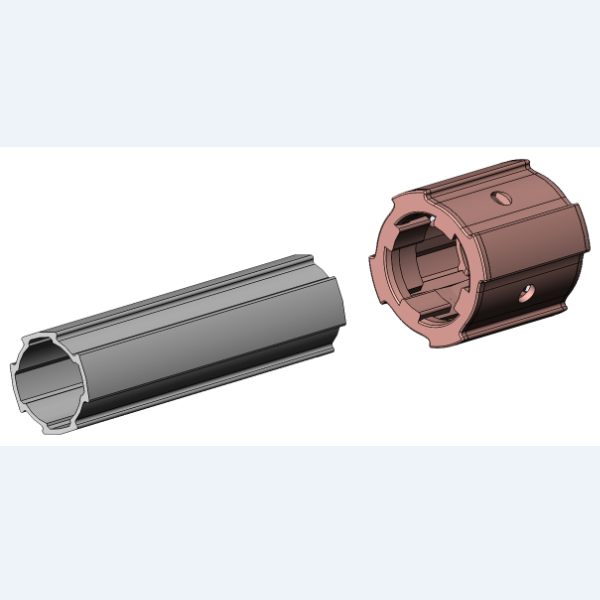

Linear translation sliding sleeve is applied to 43 series aluminum tubes, The weight of the linear sliding sleeve is only 0.032kg, which is very light. The protruding buckles on the four sides of the sliding sleeve can be installed with a variety of connectors to form a translation device.Both ends of the product are equipped with plastic sleeves to make the product look beautiful and reduce the friction between the aluminum pipe and the linear sliding sleeve.

Features

1. The weight of aluminum alloy is about 1/3 of that of metal pipe. The design is light and stable with excellent corrosion resistance.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, and the overall system is beautiful and reasonable after assembly.

4.Product diversification design, DIY customized production, can meet the needs of different enterprises.

Application

The inner ring of the aluminum alloy linear sliding sleeve has four grooves, which can well match the 43 series aluminum tube, so that it can only move horizontally along the aluminum tube. Thereby producing a translation device.The buckles protruding in the four directions of the appearance can be connected with other aluminum pipes to make it the support of the aluminum pipe racking.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Square |

| Alloy Or Not | Is Alloy |

| Model Number | 28AT-2B-100 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Temper | T3-T8 |

| Surface treatment | Anodized |

| Weight | 0.032kg/pcs |

| Material | Aluminum |

| Size | For 43mm aluminum pipe |

| Color | Sliver |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 10000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 240 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.