As one of the main varieties of aluminum processing materials, aluminum profiles are widely used in the field of construction with its unique decoration, excellent sound insulation, heat preservation and recyclability, and by virtue of its extrusion molding and high mechanical and physical properties, good thermal conductivity and high specific strength, etc. It is more and more widely used in transportation, electronics, machinery, light industry, petroleum, chemical industry, aviation, aerospace and other fields. Today, let WJ-LEAN introduce the process flow of aluminum profiles.

Step 1: Selection of raw materials

The industrial aluminum profile is an industrial frame profile obtained by heating the aluminum rod through the mold extrusion molding, and the aluminum rod is cast through the aluminum ingots, which is called the industrial aluminum profile raw materials; The raw materials will directly affect the performance of industrial aluminum products.

Step 2: Aluminum rod heating

The heating treatment of aluminum rod should ensure the control of temperature, if the temperature is too high or too low, it will directly affect the hardness of the finished product, so the temperature must be strictly controlled during the heating and cooling process;

Step 3: Mold design

Industrial aluminum profile is the final product of aluminum rod extrusion by heating through the mold, and the mold is designed according to the demand with high precision specifications, used to extrude the required specifications and cross-section of the profile products;

Step 4: Industrial aluminum extrusion

Extrusion temperature is a fundamental and critical process factor for extrusion production. The extrusion speed must be carefully controlled during the extrusion process.

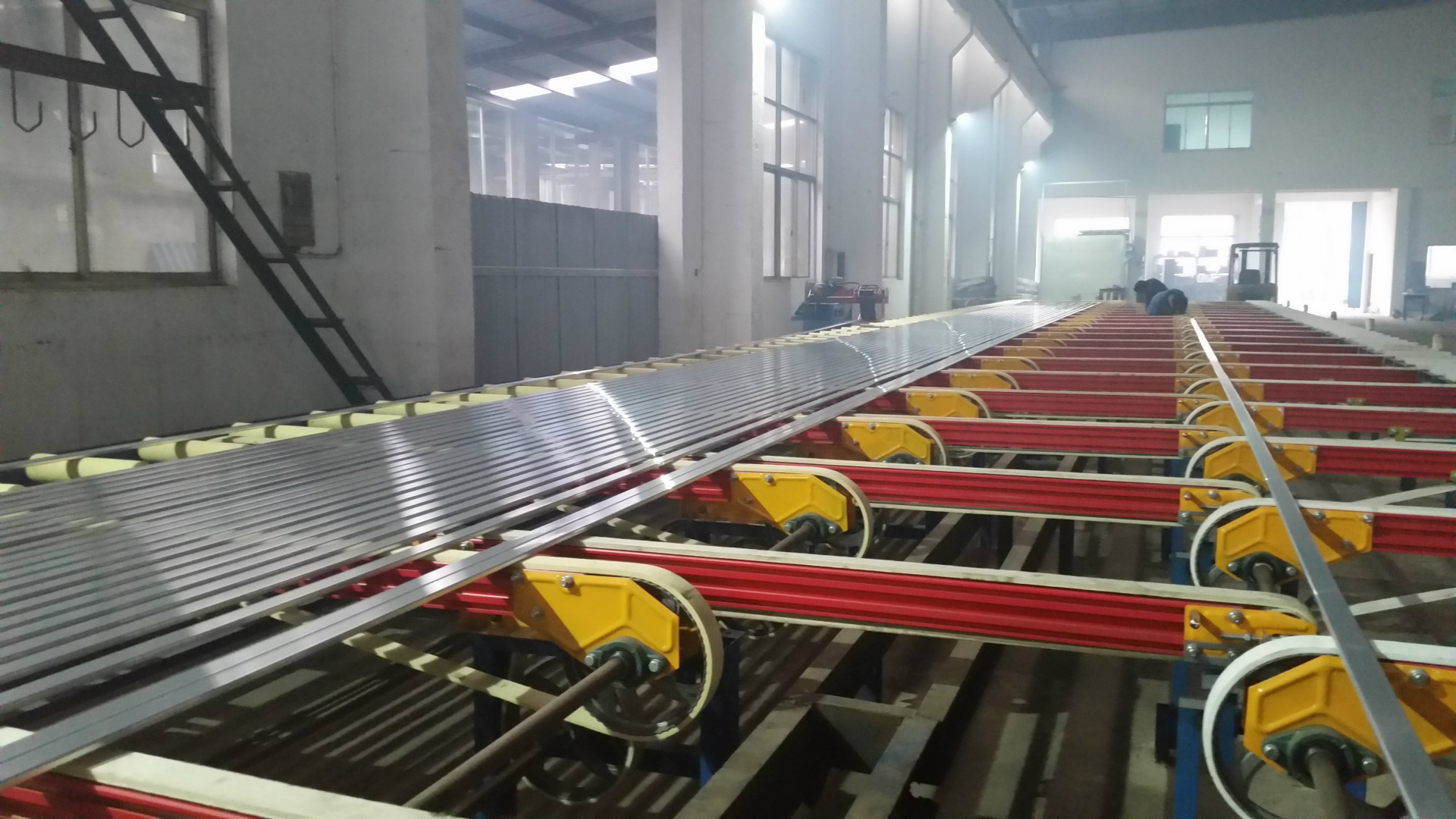

Step 5: Industrial aluminum profile straightening correction

The straightness of aluminum profiles affects whether aluminum profiles can be used in mechanical equipment, so the straightness of aluminum profiles is one of the important standards for the quality of aluminum profiles. Generally, the extruded profiles need to be straightened for straightness.

Step six: Manual aging

The aluminum profiles produced by extrusion have low hardness before aging and cannot be used as finished products, so in general, they must be aged to improve strength.

Step 7: Sand blasting

After extrusion molding, the surface of industrial aluminum profiles will have obvious stretch lines, and the surface micropores are large, relatively rough, and must be sandblasted.

Step eight: Surface oxidation treatment

General aluminum profile surface anodized silver white treatment, elegant and beautiful and corrosion resistance. Generally do this step, after cooling, the finished aluminum profile will come out.

Step 9: Packaging

Because the quality requirements of industrial aluminum products are very high, the overall beauty of the appearance is very particular, so the requirements are very strict in the later packaging.

Finished aluminum profile processing process

Step 1: Cut

The length of the aluminum profile is generally 6.01 meters, and the fine cutting of the aluminum profile is required according to the drawings. Our general cutting error is ≦0.5mm. In addition to cutting length, aluminum profiles can also be cut diagonally and diagonally.

Step 2: Drill and tap teeth

Generally, when aluminum profiles are internally connected, it is necessary to punch and tap, and the drill knives used for punching and tapping of different specifications of aluminum profiles are not the same. Therefore, punching and tapping is also one of the aspects of testing the processing strength of an aluminum profile.

Step 3: Aluminum profile fixing

After cutting and drilling, it is necessary to connect aluminum profiles with aluminum profile connectors. As long as the installation master according to the drawings installation, you can make the desired aluminum profile frame, equipment hood, pipeline workbench and so on.

Our main service:

Welcome to quote for your projects:

Contact: info@wj-lean.com

Whatsapp/phone/Wechat : +86 135 0965 4103

Website:www.wj-lean.com

Post time: Aug-14-2024