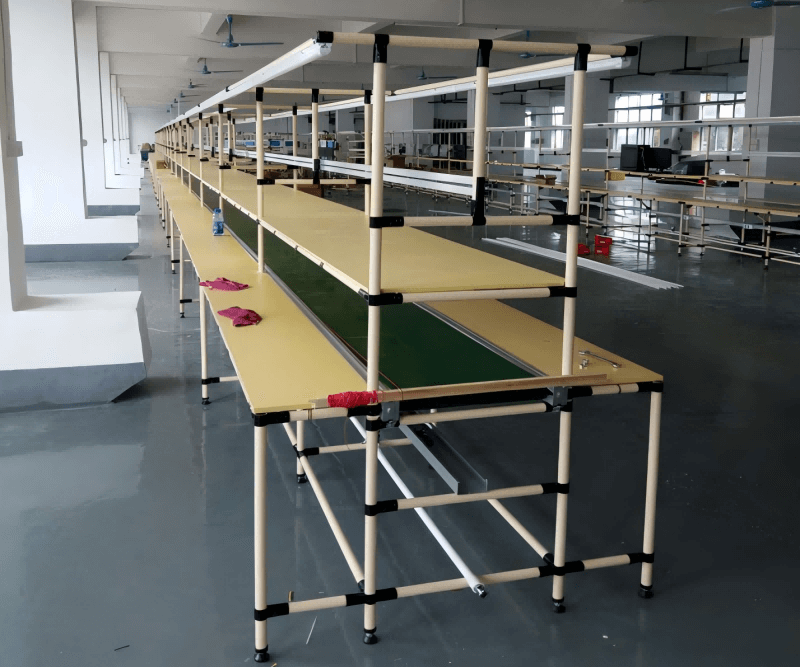

Lean and flexible production line is the carrier of our true application of lean production practice. A very common lean and flexible production line carries many lean ideas, such as the distinction of people flow and logistics, the elimination of waste, and the improvement of awareness, so how can lean and flexible production lines be designed efficiently? Below through a few points to explain the next!

1. Define the value stream: First, analyze the entire production process to define the value stream of the product, that is, the entire value chain from raw materials to the final product delivered to the customer. Identify the value and waste in each process for subsequent improvement.

2. Identify and eliminate waste: Through value stream analysis, identify all kinds of waste in the production process, such as waiting time, inventory overhang, unnecessary transportation, etc. Then, take measures to eliminate these wastes, such as optimizing production processes, reducing inventory, improving equipment layout, etc.

3. Implement process improvement: Improve the production process according to the identified waste. Lean tools such as 5S finishing, single point work, standardization work, etc. can be used to optimize production processes and improve efficiency and quality.

4. Introduction of automation technology: In lean production lines, the introduction of automation technology can be considered to improve production efficiency and quality stability. For example, the use of automation equipment and robots to replace manual operation, reduce the interference of human factors, and improve the stability and consistency of the production line.

5. Cultivate employees' awareness of participation: The success of lean production line is inseparable from employees' active participation and awareness of continuous improvement. Therefore, it is necessary to cultivate the sense of participation of employees, encourage them to make suggestions for improvement, and provide training and support so that they can better adapt to and promote the implementation of lean production.

6.Continuous improvement: Lean production is a process of continuous improvement, which requires continuous monitoring and evaluation of the effect of the production line, and adjustment and improvement according to the actual situation. Regular evaluation and improvement of the production line to ensure continuous and efficient operation.

Our main service:

Creform pipe system

Karakuri system

Aluminum profile system

Welcome to quote for your projects:

Contact: info@wj-lean.com

Whatsapp/phone/Wechat : +86 135 0965 4103

Website:www.wj-lean.com

Post time: Aug-29-2024