The common lean tubes in the market are mainly divided into three types:

1. The first generation of Lean tube

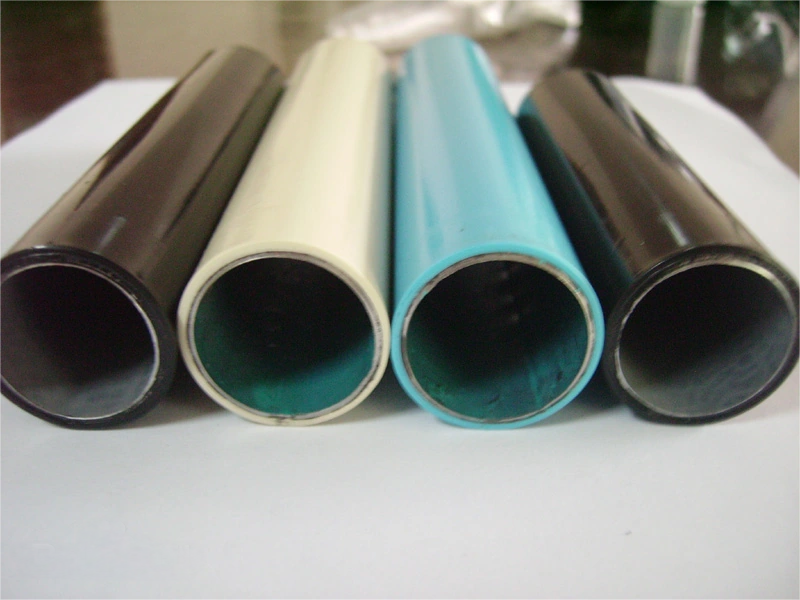

The first generation of lean pipe is the most used kind of lean pipe, but also the most common kind of wire rod. Its material is the outer plastic coating of steel pipe, and the inside is maintained with special materials to prevent rust. Domestic producers are mostly concentrated in Shenzhen, especially in Bao 'an District. Vicious price competition directly leads to manufacturers to do something about production costs, in order to control costs, a few manufacturers will reduce the wall thickness, so that the load is also reduced. There are also a few manufacturers insist on quality, do not participate in the price war, the use of 2.5MM SPCC as raw materials for the production of connecting parts, the metal layer of the pipe is thick enough, the anti-rust paint is uniform, and the safety of this pipe is high enough. Therefore, there is a sharp contrast in the quality of lean management products on the market now. There is a difference in price. Users who really have needs can't just look at the price.

Features:

The price is low, which can reduce the cost.

The finished products are diverse in color, the connector products are very complete, and the surface treatment is electrophoretic, chrome plating, galvanized, nickel plating.

The load is related to the design, and a good design can have a high load bearing. It is the best choice for cost performance.

2, the second generation of lean tube

The second generation of lean pipe uses stainless steel as its material, which improves a lot in appearance. In addition, stainless steel also has the function of corrosion prevention. However, the load of stainless steel is lighter, and the price is slightly higher than that of the first generation of wire rods. Overall, the cost performance is not very high.

Features:

Stainless steel, corrosion and rust resistant

The cost is low and the market competition is fierce

Not as widely used as the first generation

The connector installation is cumbersome, and the appearance is improved compared with the first generation

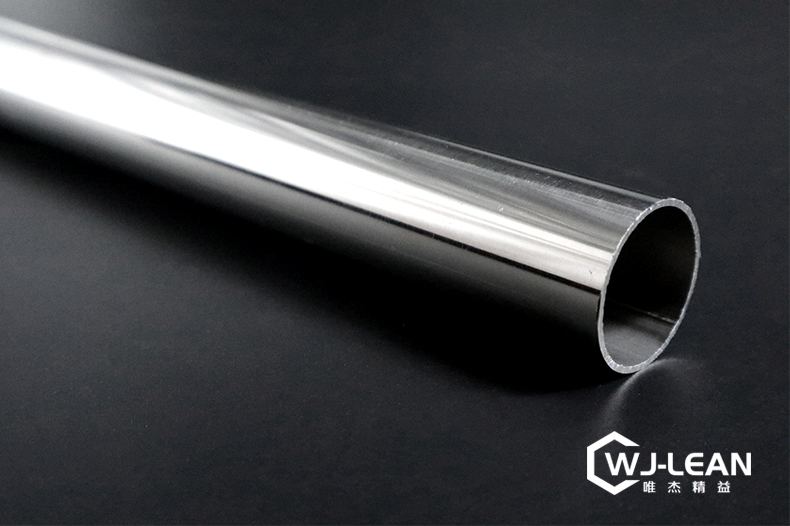

3, the third generation of lean tube

The third generation of lean tube is made of aluminum alloy, and the appearance is silver white. The surface is anodized for permanent corrosion and rust prevention. There are also many improvements in connectors and fasteners. Its fasteners are made of die-cast aluminum, which enhances the hardness and stiffness. Load capacity improved over the first generation rod.

Features:

Aluminum alloy material, surface anodizing treatment, corrosion and rust prevention

The connector is convenient for loading and unloading and elegant in appearance

Suitable fittings allow quick connection and fastening of third party parts

Representative of modern flexible production

Maintain workshop and factory environment

Our main service:

Welcome to quote for your projects:

Contact: info@wj-lean.com

Whatsapp/phone/Wechat : +86 135 0965 4103

Website:www.wj-lean.com

Post time: Aug-02-2024