Karakuri Kaizen have gained increasing attention in recent years and continue to change how we utilise natural elements to achieve lean and green manufacturing. The automation of the Karakuri system has brought the following changes to humans:

1. In the industrial field:

• Increased production efficiency: Karakuri systems can automate many repetitive and labor-intensive tasks in the industrial production process. For example, in material handling and parts assembly, these automated systems can work continuously and accurately, greatly improving the speed and quality of production, and reducing the time and labor costs required for production.

• Improved work safety: By replacing humans in some dangerous and high-risk operations, such as working in high-temperature, high-pressure, and toxic environments, the Karakuri system reduces the occurrence of work-related accidents and protects the safety of workers.

• Promoted lean production: It helps to achieve leaner production processes. By relying on simple mechanical structures and principles such as gravity and inertia, Karakuri systems can minimize waste in the production process, improve the utilization rate of resources, and be more conducive to continuous improvement of production processes.

2. In the service industry:

• Enhanced service experience: In the food service industry, for example, Karakuri systems can be used for food dispensing and preparation, providing customers with more accurate and customized services. Customers can choose their desired food combinations and portions, improving the overall service experience and satisfaction.

• Optimized operational efficiency: In service scenarios such as restaurants and supermarkets, the use of Karakuri systems can automate processes such as checkout and goods sorting, reducing queuing time for customers and improving the operational efficiency of the business.

3. In terms of human lifestyle and work patterns:

• Alleviated labor intensity: The automation of the Karakuri system reduces the need for humans to engage in heavy physical labor, allowing people to shift their focus to more creative and intellectual work, thereby alleviating the physical burden on workers.

• Promoted the transformation of skills: As automation technology develops, it requires workers to acquire new skills and knowledge, such as programming, equipment maintenance, and system operation, to adapt to the changes brought about by automation, which promotes the transformation and upgrading of human skills.

Our main service:

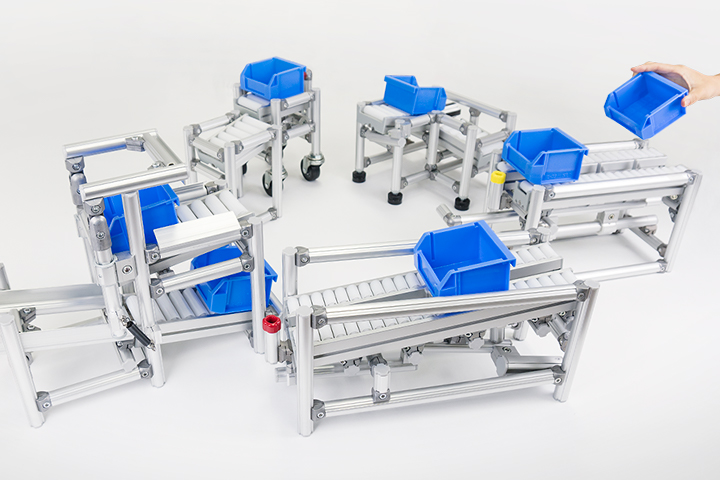

·Karakuri System

·Aluminum profie System

·Lean pipe System

·Heavy Square Tube System

Welcome to quote for your projects:

Contact: zoe.tan@wj-lean.com

Whatsapp/phone/Wechat : +86 18813530412

Post time: Nov-05-2024