The following are the main differences between the third-generation lean tube and previous aluminum profiles:

Material

Third-generation lean tube: It is made of aluminum alloy, which combines the advantages of light weight, high strength, and good corrosion resistance.

Previous aluminum profiles: Generally refer to traditional aluminum profiles, which may have relatively simple alloy compositions or surface treatments compared to the third-generation lean tube.

Surface treatment

Third-generation lean tube: The surface is usually treated by anodizing, which can provide better corrosion resistance, wear resistance, and a more durable and aesthetically pleasing appearance. This anodic oxide film can also enhance the hardness and scratch resistance of the surface, making it more suitable for use in various environments.

Previous aluminum profiles: They may have different surface treatment methods such as electrophoresis, powder coating, or mechanical polishing. While these treatments can also improve the appearance and corrosion resistance to a certain extent, the performance and durability may not be as good as the anodized surface treatment of the third-generation lean tube.

Connector design

Third-generation lean tube: Its connectors and fasteners have been improved, often made of die-cast aluminum material, which enhances hardness and stiffness. The design of the connectors is more user-friendly, making it easier to load and unload, and can be quickly connected and fastened to third-party parts. This allows for more convenient assembly and disassembly, improving work efficiency and flexibility during installation and maintenance.

Previous aluminum profiles: The connectors of traditional aluminum profiles may not have such advanced design and material selection, and may require more complex installation tools and techniques during assembly. In some cases, additional processing or adjustments may be needed to ensure a firm connection, which may increase installation time and labor costs.

Weight

Third-generation lean tube: Thanks to the use of aluminum alloy materials and optimized design, the weight of a single aluminum tube is much lighter than that of a single traditional lean tube or some previous aluminum profiles. This makes the assembled workbenches, shelves, or other structures made of third-generation lean tubes lighter in weight, which is beneficial for easy handling, transportation, and relocation.

Previous aluminum profiles: Depending on the specific type and thickness, the weight of previous aluminum profiles may vary, but in general, they may be relatively heavier compared to the third-generation lean tube, especially when considering the overall structure after assembly.

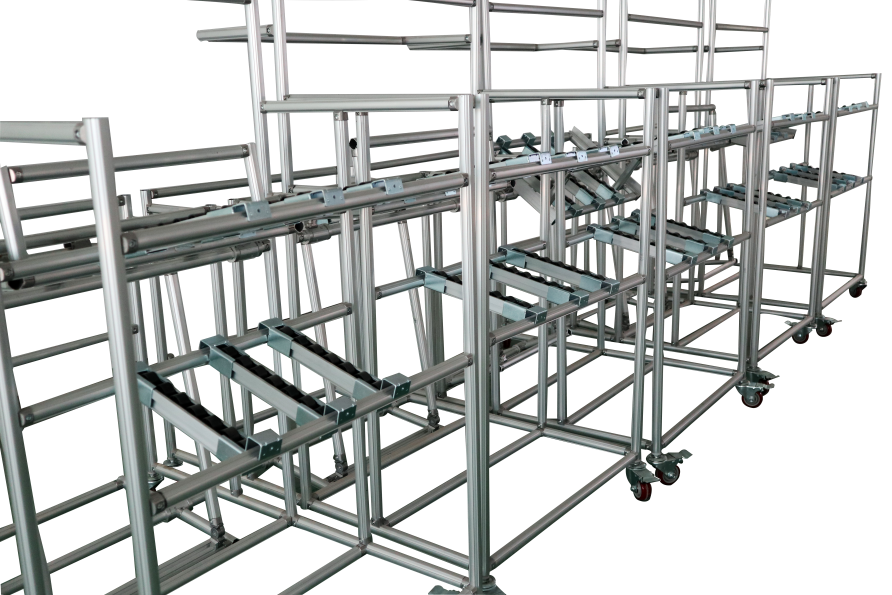

Application scenarios

Third-generation lean tube: Due to its light weight, corrosion resistance, and convenient assembly, it is widely used in industries such as electronics manufacturing, pharmaceuticals, food processing, and logistics warehousing, especially in scenarios where frequent layout adjustments or equipment relocation are required, such as electronics production lines, clean workshops, and warehouses for light-duty goods.

Previous aluminum profiles: They also have a wide range of applications, including construction (such as doors, windows, and curtain walls), automotive manufacturing, mechanical equipment manufacturing, and other fields. In some applications where higher strength and rigidity are required, such as the framework of heavy machinery or the structure of large buildings, thicker and stronger aluminum profiles may be used.

Cost

Third-generation lean tube: In general, the production process and material cost of the third-generation lean tube may be relatively optimized, resulting in a more competitive price in the market. At the same time, its long service life and low maintenance cost also make it more cost-effective in the long run.

Previous aluminum profiles: The cost of previous aluminum profiles may vary depending on factors such as alloy type, processing technology, and surface treatment. Some high-performance or special-purpose aluminum profiles may have relatively high costs, while some common aluminum profiles may have more stable prices. However, compared with the third-generation lean tube, they may not have obvious advantages in terms of cost performance in some specific application scenarios.

Our main service:

·Heavy Square Tube System

Welcome to quote for your projects:

Contact: zoe.tan@wj-lean.com

Whatsapp/phone/Wechat : +86 18813530412

Post time: Nov-28-2024