The lean pipe workbench is a 6063-T5 lightweight aluminum profile product developed on the basis of the industrial aluminum profile product system. It has good tensile strength and support strength. It is used with standard lean pipe accessories. It is easy and quick to assemble and can be used in humid working environments. It does not rust or slag and is durable. It is one of the most widely used aluminum profile products.

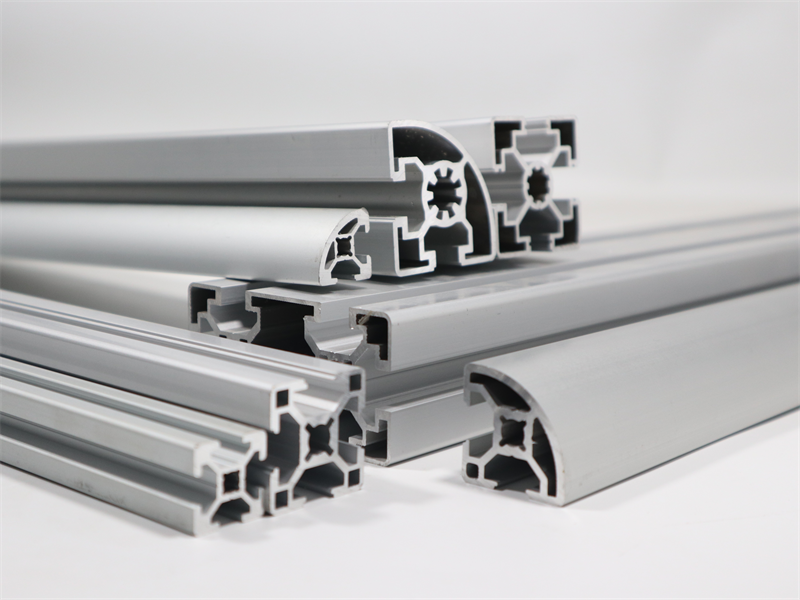

The material of the lean tube workbench is the same as that of aluminum profiles. It is an aluminum alloy product extruded by heating aluminum rods. The cross-section shape is a round tube with a diameter of 28mm. There are 4 grooves on the periphery, which is convenient for using lean tube connection accessories. Only an inner hexagonal wrench is needed to complete manual assembly and build various styles of workbenches. It has the following advantages:

1. Low cost

In actual production, each enterprise must control the production cost within the lowest range to ensure the maximum profit. The lean tube workbench is made of aluminum profile material, which has a light quality. The middle is a hollow tube. If there is no special requirement, the wall thickness will generally not exceed 2.0mm. Because its chemical formula adds no less than 0.9% magnesium, the hardness of the lean tube workbench reaches 62HB, which is twice that of stainless steel. It has a good load-bearing capacity. Within the range of ensuring the load-bearing capacity, it can also constitute a low-cost investment, making the lean tube workbench deeply favored by the light industry.

2. Easy to assemble

The lean pipe workbench uses a 28mm diameter, cross-shaped vertical bidirectional positioning hollow round pipe, equipped with special lean pipe connection accessories, forming a modular system. No welding and other machining are required. Only a hexagonal wrench is needed. Different fasteners and different connection methods can be selected according to the cutting size. The sizes of pipes and accessories are developed according to the size matching. There will be no situation of taking the wrong accessories during assembly. There is no need to deliberately train the assemblers and they can go to work at any time. A group of two can complete the assembly task in a short time, which greatly shortens the construction period, reduces work pressure, and reduces production costs.

3. In line with the principles of ergonomics

Human energy is limited. Working too long will make the human body enter a state of fatigue, which not only affects work efficiency, but also may cause serious work-related accidents due to fatigue. The lean tube workbench utilizes the ductility and easy processing performance of aluminum profiles. It can be cut into any length according to the size. According to the arm length and height of the human body, it can be built into a lean tube workbench of different heights. It can be sat or stood, so that the operator can switch back and forth between sitting and standing. Sitting can relax the muscles, increase the blood circulation of the brain and the whole body, and improve work efficiency; standing can temporarily relieve the lower limbs of the human body, adjust the coordination between joints and muscles, prevent blood from accumulating in the feet of the human body, and facilitate blood circulation throughout the body, so that the hands and brain can be used together, which is more conducive to improving work efficiency.

The assembly method of the lean tube is very flexible. It can be used alone or in combination. After installing the universal casters, the lean tube workbench and the aluminum profile workbench with different functions can be mixed and matched to form a new lean production system with more functions. In addition, the humanized design of the lean tube workbench is suitable for people of any size to operate. They can stand or sit freely and switch freely, so that the human body can relax and keep a clear working mind at all times, reduce the probability of operating errors, conform to the principles of ergonomics, and have a modern working mode, which can make boring work in a pleasant way.

The lean tube workbench is produced according to the standard of 6063-T5 aluminum profiles. The surface is anodized and sandblasted, which has a good anti-oxidation effect. It will not cause secondary pollution to the product when used in harsh production environments. It is easy to use in light workshops. With the advantage of low cost, the use effect is not inferior to other workbenches.

Our main service:

·Heavy Square Tube System

Welcome to quote for your projects:

Contact: zoe.tan@wj-lean.com

Whatsapp/phone/Wechat : +86 18813530412

Post time: Nov-20-2024