OEM Customized Lean Flow Racking - Inner corner joint pipe joint system connector – WJ-LEAN

OEM Customized Lean Flow Racking - Inner corner joint pipe joint system connector – WJ-LEAN Detail:

Product introduction

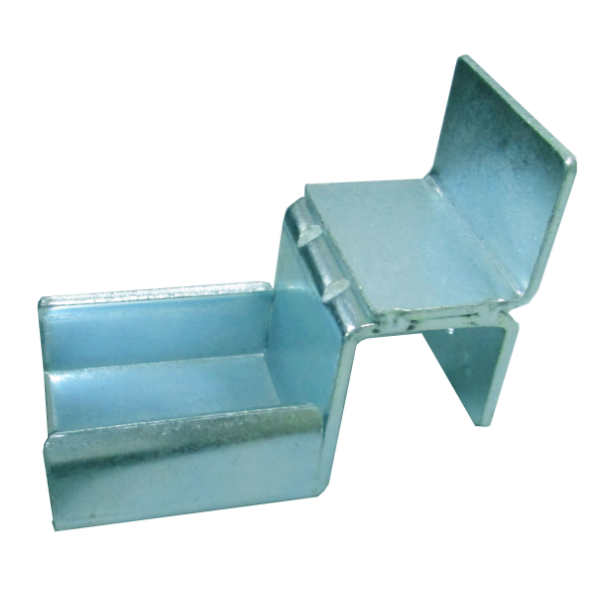

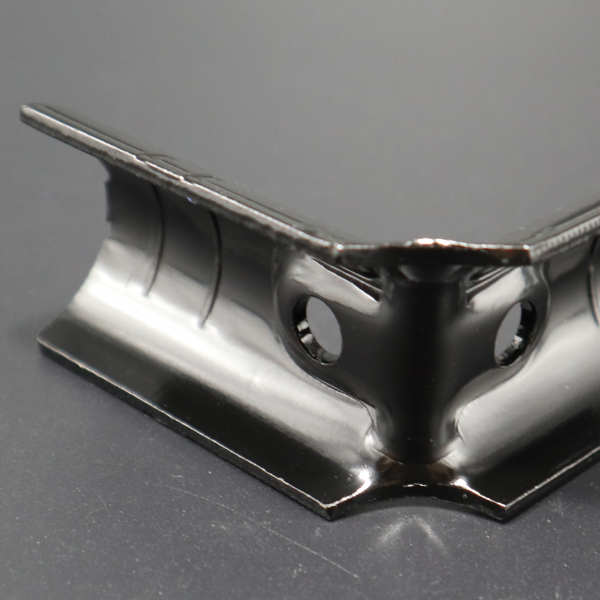

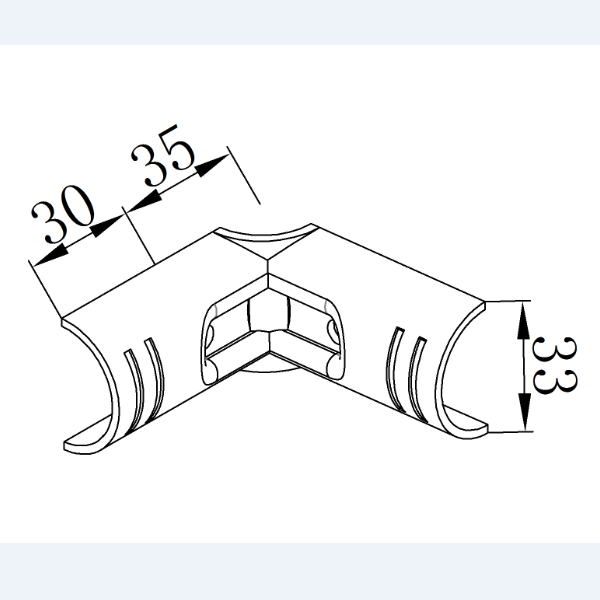

The inner right angle joint W-2 is a common joint in the lean pipe system. It can be combined with the outer right angle joint W-3 and two pairs of M6 * 25 screws and nuts to form a 90 degree joint structure. As an important part of the lean pipe racking.The joint is stamped from 2.5mm thick raw material. The stability of the structure can be guaranteed. The joint is also grinded, which can effectively reduce the burr of the joint, improve the aesthetic degree and avoid the scratch of the user.

Features

1. Two equipotential lines on both sides of the product, so the installation position of the tube can be known when using. Auxiliary user installation.

2.The thickness of the product is up to 2.5, 25% thicker than most products, with stronger performance and higher bearing capacity.

3. Holes are reserved on the surface of the product, and self-tapping screws can be inserted later to better fix the pipe.

4. Products can be customized with logos and marked with models according to different needs of customers.

Application

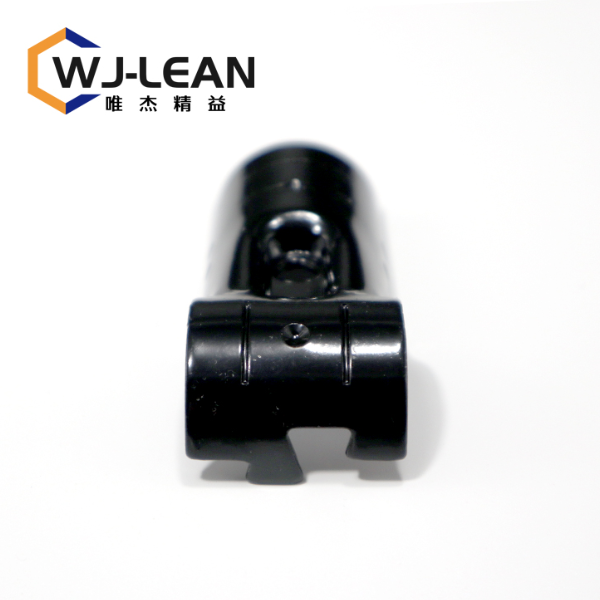

The inner right angle joint is an important component of a lean pipe racking, which together with the outer right angle joint forms the outer frame of the shelf. This product is easy to install. It only needs a wrench to complete the whole installation process. It can fix the positions of three lean pipes at the same time. You can even build a complete lean pipe racking with only inner right angle joint, outer right angle joint and T-type direct joint.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | W-2 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Technics | stamping |

| Thickness | 2.5mm |

| Weight | 0.091kg/pcs |

| Material | Steel |

| Size | For 28mm pipe |

| Color | Black, Zinc, Nickel, Chrome |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 20000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 250 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

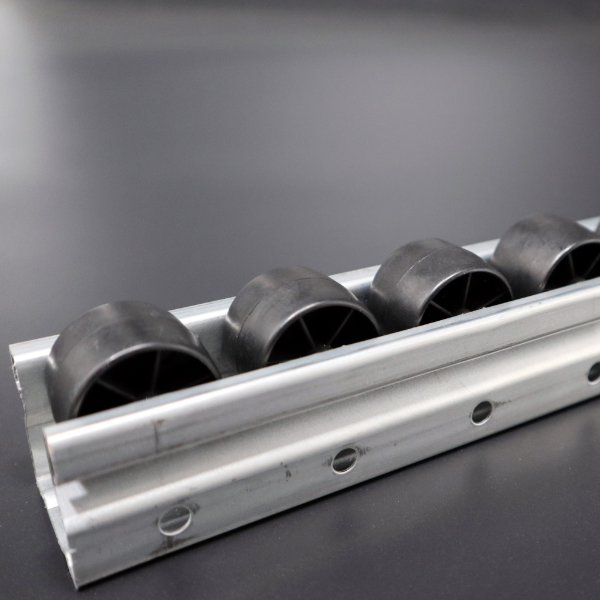

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for OEM Customized Lean Flow Racking - Inner corner joint pipe joint system connector – WJ-LEAN , The product will supply to all over the world, such as: Czech Republic, Japan, Sao Paulo, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!