Plastic joints for roller placon and lean tube protection

Product introduction

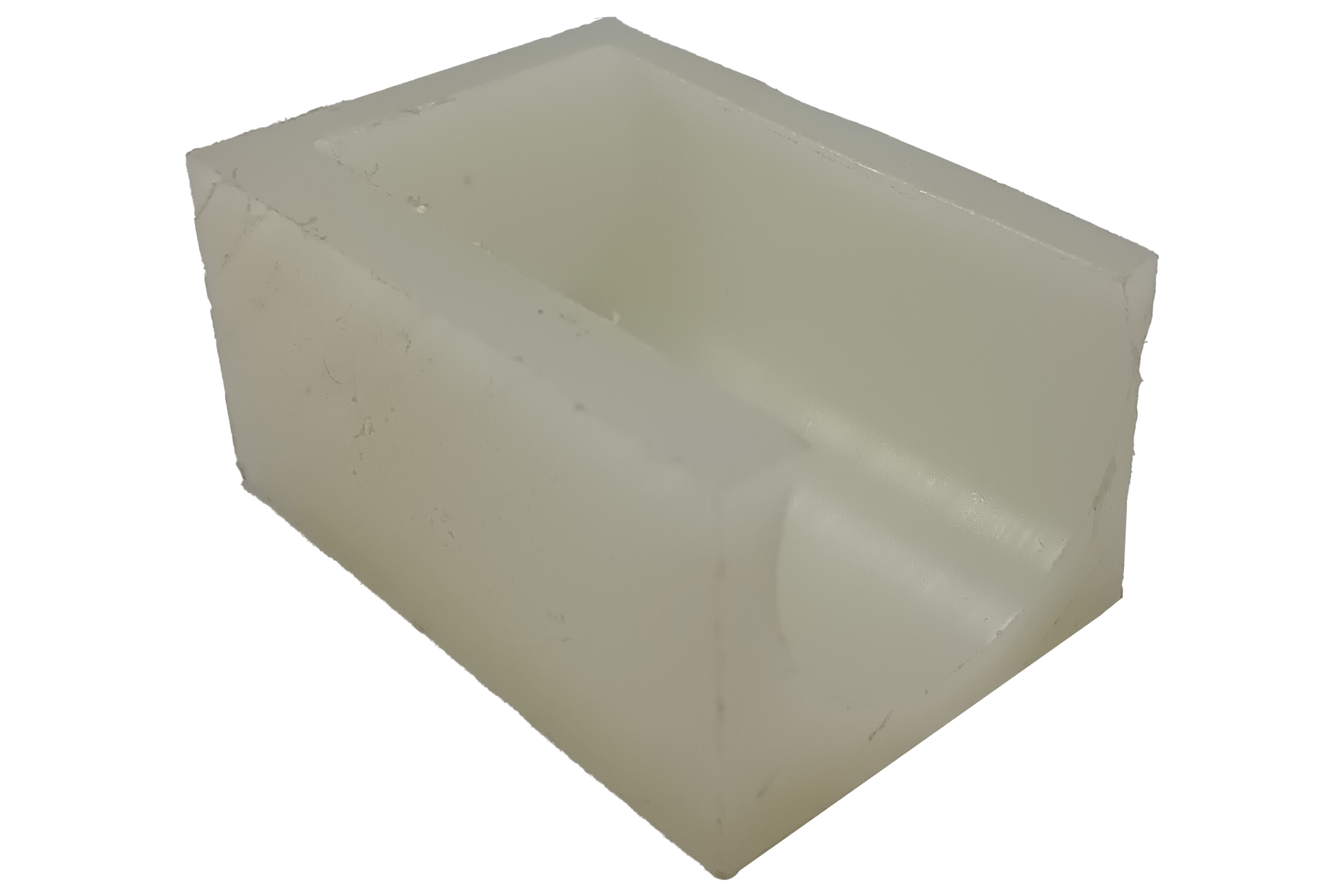

Our innovative plastic joints designed to provide exceptional protection and support for roller placon and lean tube systems. Our plastic joints are engineered to deliver superior performance and durability, making them an essential component for optimizing the functionality and longevity of your roller placon and lean tube setups.Crafted from high-quality materials, our plastic joints are built to withstand the rigors of daily use, ensuring reliable and long-lasting performance. The robust construction of these joints provides a secure and stable connection, effectively safeguarding your roller placon and lean tube systems from damage and wear

Features

1.产品外观精美,防锈、耐腐蚀。

2.组装简便,整个安装过程不需要螺丝。

3.滚轮轨道接头采用高强度材料,使用寿命长,不易变形,可重复使用。

4.款式多样,可满足不同场合的需求。

Application

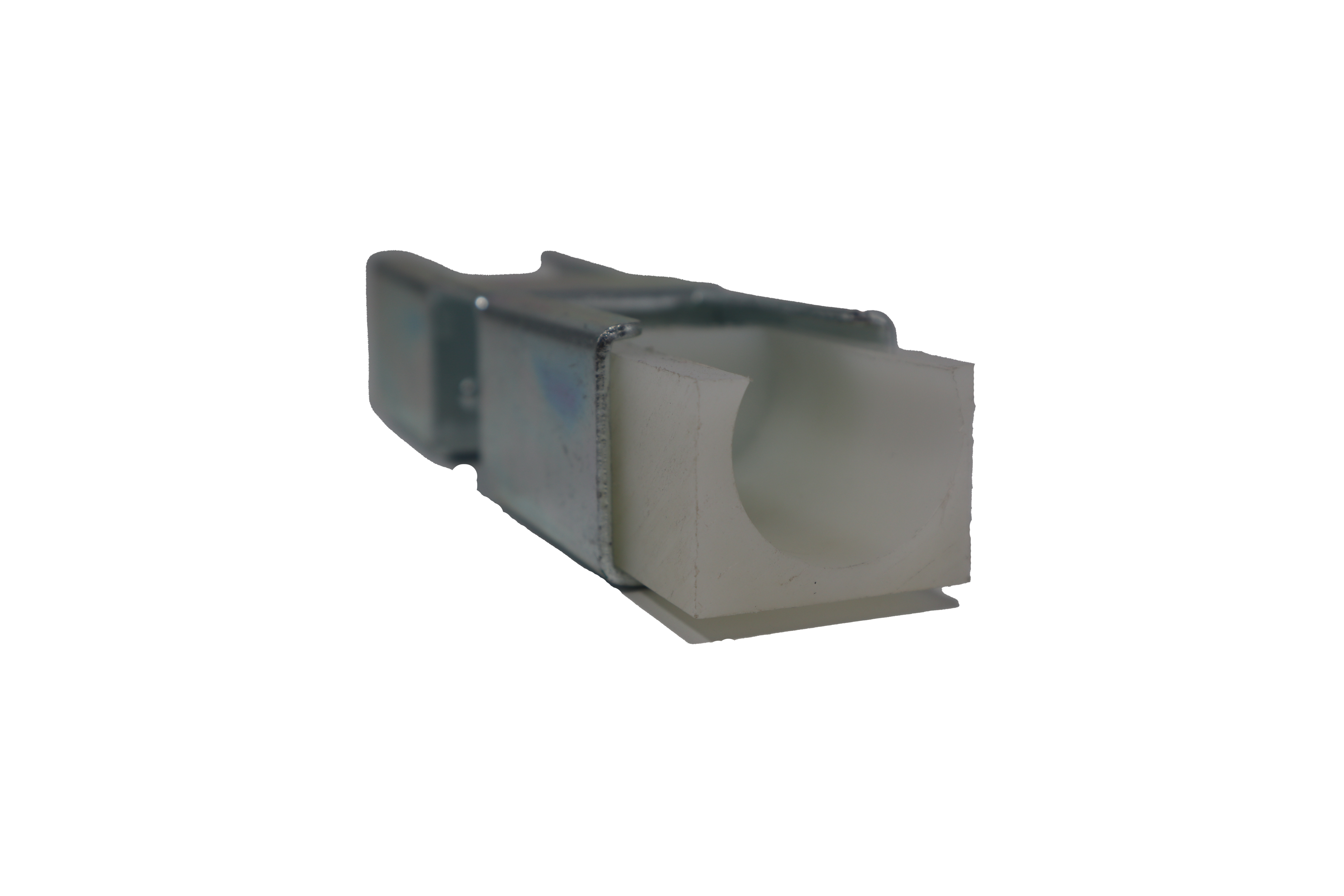

This joint is mainly used at the tail of the roller track and is a stop part of the conveyor belt. Because its welded edge can stop the transport container, it is a key part of the first in first out shelf. RTJ-2040CD can also be well used in the tool rack truck. The inclined slide rail makes the container with tools incline to the user's side. The roller track joint at the lower position of the roller track makes the container fixed, which is convenient for the user to access the tools.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Not |

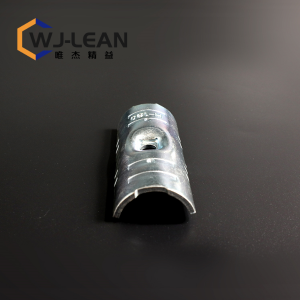

| Model Number | WJP-19 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Temper | T3-T8 |

| Groove width | 40mm |

| Weight | 0.01kg/pcs |

| Material | Plastic |

| Size | For Roller Track |

| Color | White |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, etc. |

| Transportation | Ocean |

| Packing | 100 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.