Professional Design Piping Joints - Galvanized steel adjust racking bottom accessories – WJ-LEAN

Professional Design Piping Joints - Galvanized steel adjust racking bottom accessories – WJ-LEAN Detail:

Product introduction

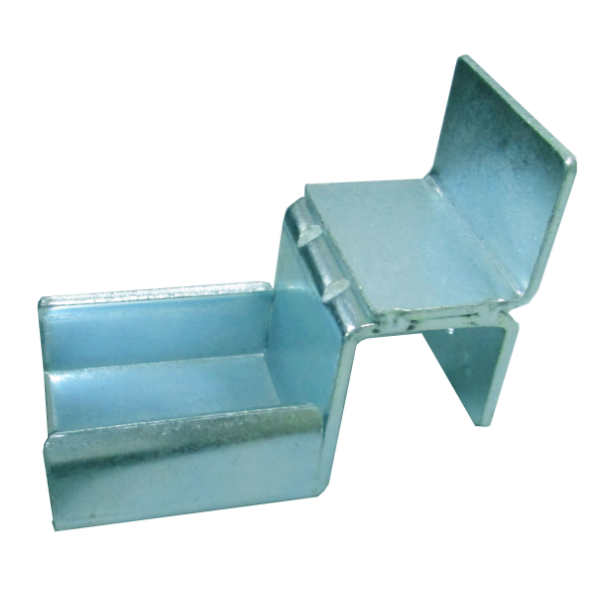

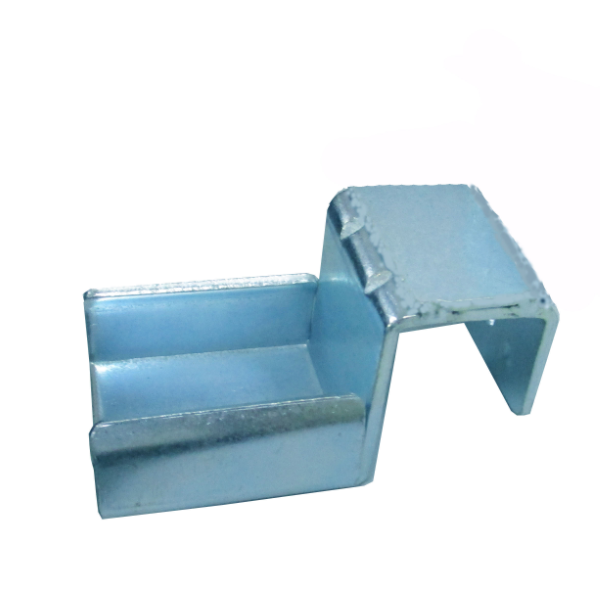

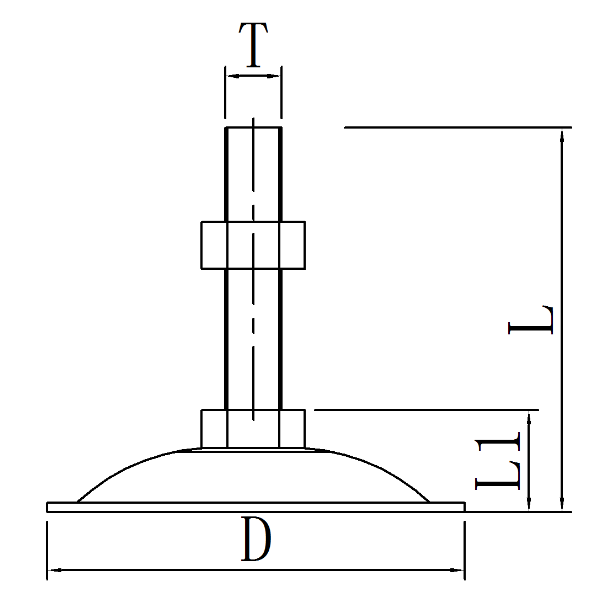

As the bottom support part of the lean pipe racking, adjust needs to be durable, high hardness and high bearing capacity. Wj-lean’s metal adjust is made of galvanized steel, which can significantly delay rusting and corrosion. Thereby extending the service life of the metal parts. The adjust is composed of a screw and a chassis. It is a commonly used mechanical part for adjusting the height of the equipment through the rotation of the screw. Our adjust stem diameter has M10 and M12.

Features

1.The screw rod is made of galvanized steel, which can effectively prevent rust and corrosion.

2.The adjust chassis is thick enough, with strong bearing capacity and not easy to deform.

3.The connection between the screw rod and the chassis is fixed by nuts, which can ensure that the chassis is not easy to loosen after long-term use.

4.The screw thread is obvious and can be repeatedly inserted and used without affecting its function.

Application

Adjust is also called adjustable foot. It is a mechanical part that uses thread to adjust height; The height can be adjusted according to the use requirements, which conforms to ergonomics.It is usually used with the copper sleeve of the pipe to provide support and fixation for the bottom of the rack. It is used to adjust the height, level and inclination of different equipment.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | AD3 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Material | Iron alloy |

| Characteristic | Simple |

| Weight | 0.09kg/pcs |

| Material | Steel |

| Size | For 28mm pipe |

| Color | Zinc |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 200 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Professional Design Piping Joints - Galvanized steel adjust racking bottom accessories – WJ-LEAN , The product will supply to all over the world, such as: Orlando, Qatar, Portugal, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.