professional factory for Gravity Fed Racking - Metal fixings lean pipe system accessories – WJ-LEAN

professional factory for Gravity Fed Racking - Metal fixings lean pipe system accessories – WJ-LEAN Detail:

Product introduction

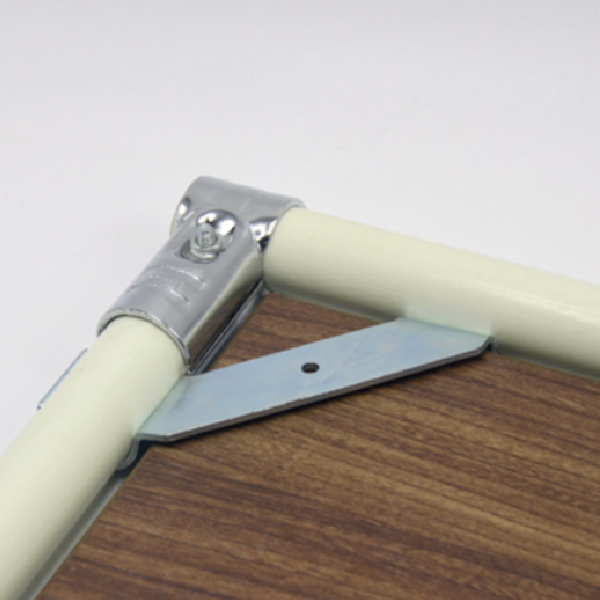

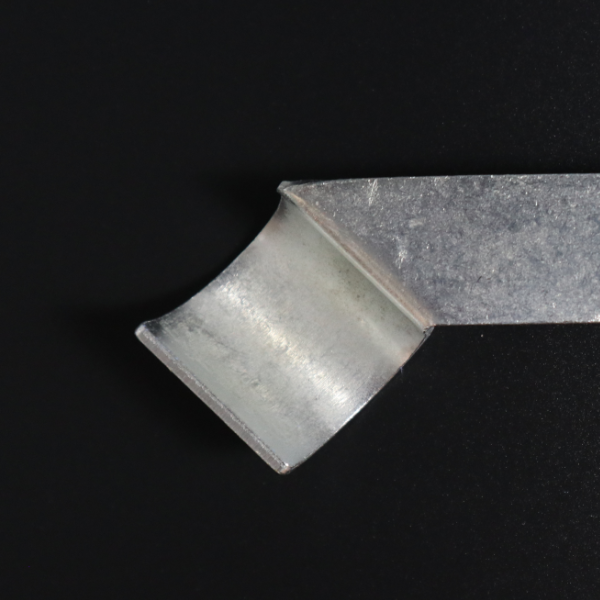

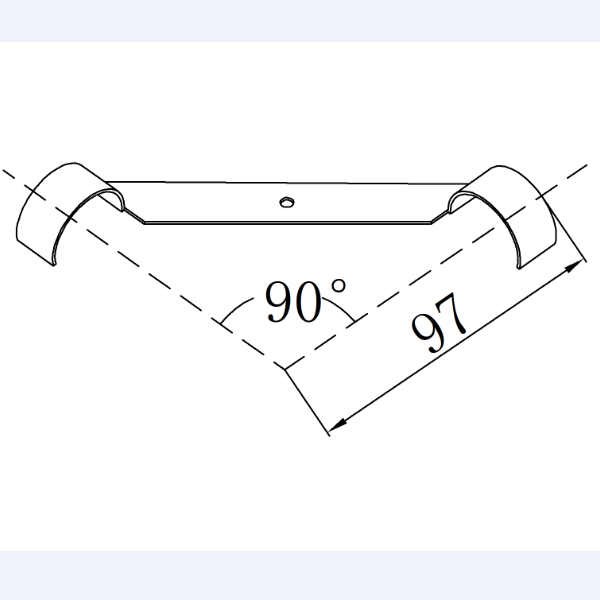

The fixed angle code of laminate is a kind of fastener. The arcs on both sides of it can be just fixed in the right angle formed by two lean pipes, thus forming a stable triangular structure. It can effectively prevent the deformation of the lean pipe shelf due to long-term use. There is a hole in the fixed corner of the laminate, and self tapping screws can be driven to further fix the board. Of course, the circular arc on both sides can also keep the hole position, which is convenient for fixing the corner code of the laminate and the pipe.

Features

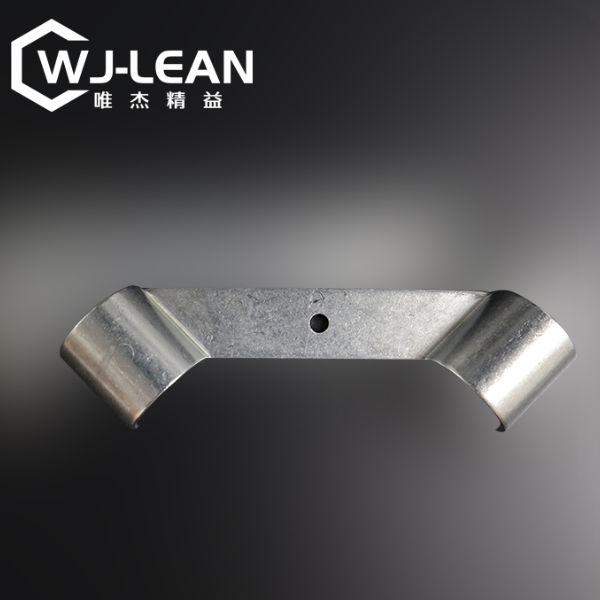

1.The fixed corner code is made of galvanized steel, which can effectively prevent rust and corrosion.

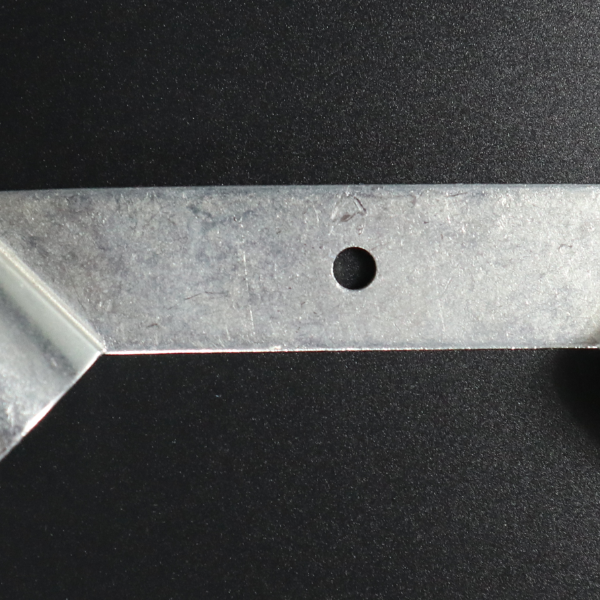

2.The thickness of the fixed corner is sufficient, the bearing capacity is high and it is not easy to deform.

3.The arc part of the product matches the outer diameter of the lean pipe, and can be fixed without screws.

4.Screw holes are reserved in the middle of the product to facilitate subsequent self tapping screws for fixation.

Application

The fixed angle code of the laminate can fix the corner of the lean pipe shelf by building a triangle with the corner of the lean pipe shelf, so that the lean pipe shelf becomes stable and avoids deformation.Holes can be reserved on both sides of the arc, so that the user can drive screws by himself, so that the fixed angle of the laminate and the pipe can be further fixed.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

| Model Number | WA-3A |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Technics | stamping |

| Characteristic | Simple |

| Weight | 0.025kg/pcs |

| Material | Steel |

| Size | For 28mm pipe |

| Color | Zinc |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 200 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for professional factory for Gravity Fed Racking - Metal fixings lean pipe system accessories – WJ-LEAN , The product will supply to all over the world, such as: United Arab Emirates, Libya, Toronto, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!