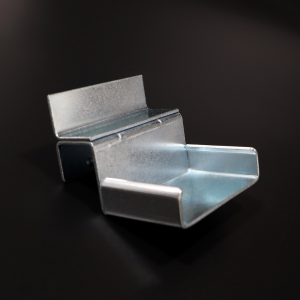

Swivel Joint for Lean Pipe Flex Tube System Assembly

Product introduction

The advanced design of the swivel joint features a seamless swivel mechanism that allows for easy alignment and connection of coated pipes at different angles.Its rugged design and corrosion-resistant coating make it suitable for use in demanding environments, providing a reliable solution for fluid handling, material transport and structural support within coated piping systems. This feature simplifies the assembly process, saving time and effort while ensuring a safe and precise fit. Whether used in a manufacturing facility, warehouse or assembly line, this component facilitates seamless integration and adaptability to improve overall operational efficiency.

Features

1. Two equipotential lines on both sides of the product, so the installation position of the tube can be known when using. Auxiliary user installation.

2.The thickness of the product is up to 2.5, 25% thicker than most products, with stronger performance and higher bearing capacity.

3. Holes are reserved on the surface of the product, and self-tapping screws can be inserted later to better fix the pipe.

4. Products can be customized with logos and marked with models according to different needs of customers.

Application

WJ-LEAN’s parallel single-side swivel metal joint is used with plastic joint WJP-06 to form a single-side rotatable structure of two pipes, mainly used for hinge structure, and needs to be equipped with a set of M6 bolts. The groove on the joint surface can increase the friction between the joint and the pipe, making it more stable. Moreover, the connection between the connector and the lean pipe conforms to human mechanics. Parallel single-side swivel metal joint is often used in various material racks and turnover vehicles. It is the most commonly used joint in the lean pipe system.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Equal |

| Alloy Or Not | Is Alloy |

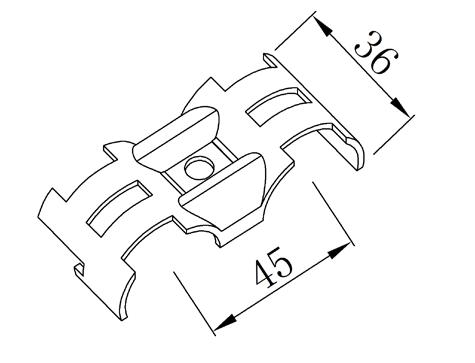

| Model Number | W-9 |

| Brand Name | WJ-LEAN |

| Tolerance | ±1% |

| Technics | stamping |

| Thickness | 2.5mm |

| Weight | 0.07kg/pcs |

| Material | Steel |

| Size | For 28mm pipe |

| Color | Black, Zinc, Nickel, Chrome |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 10000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, etc. |

| Transportation | Ocean |

| Packing | 200 pcs/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean's products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.