The third generation lean pipe aluminum alloy pipe – WJ-LEAN

The third generation lean pipe aluminum alloy pipe – WJ-LEAN Detail:

Product introduction

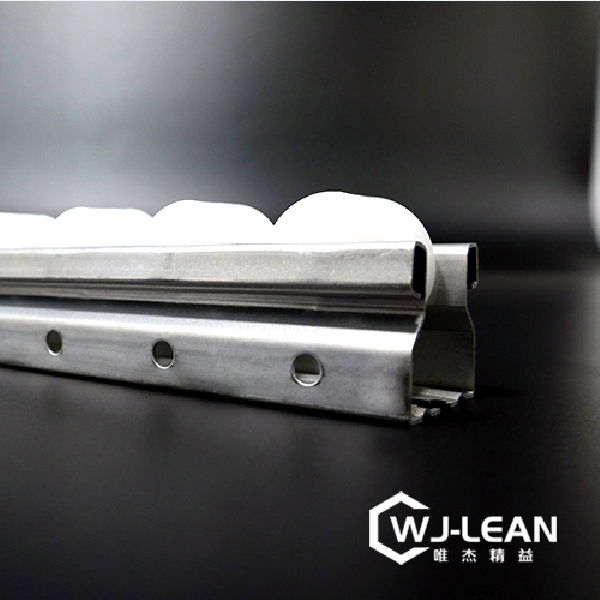

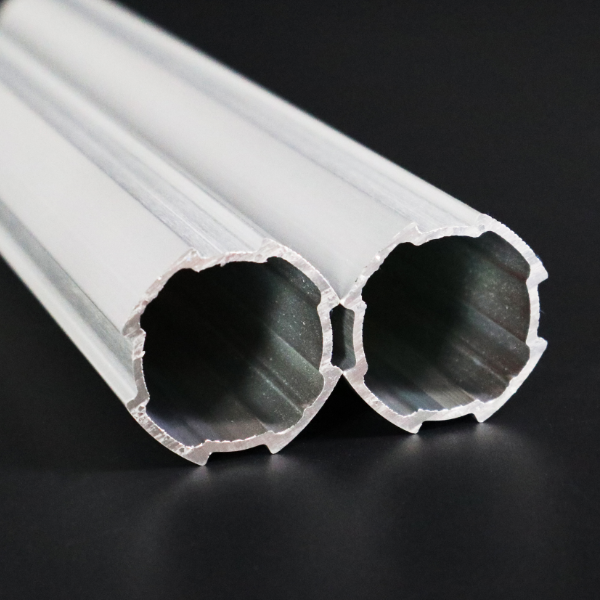

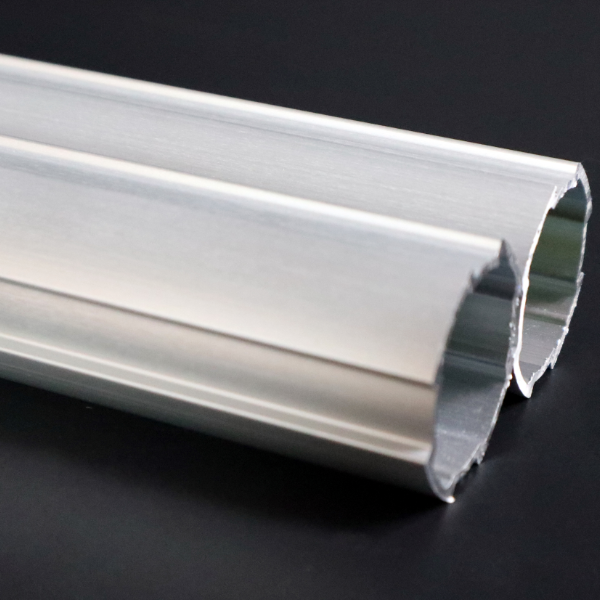

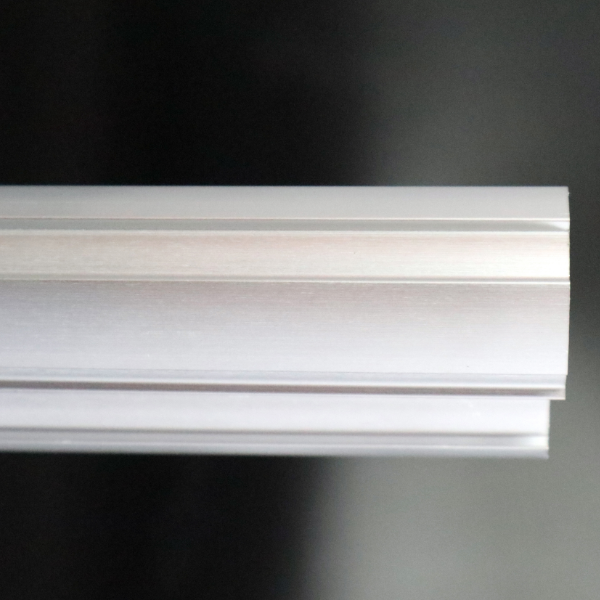

The aluminum tube with a thickness of 1.2mm can provide the user with sufficient bearing capacity. Compared with the traditional lean pipe, the aluminum pipe has less resin coating. Because the supporting connectors are also aluminum materials, it is easy to recycle when doing waste treatment. Moreover, the surface of the aluminum pipe is treated with acid resistant aluminum, and it can be kept beautiful for a long time without maintenance. At the same time, the aluminum tube surface is also coated to reduce oxidation and keep the factory clean.

Features

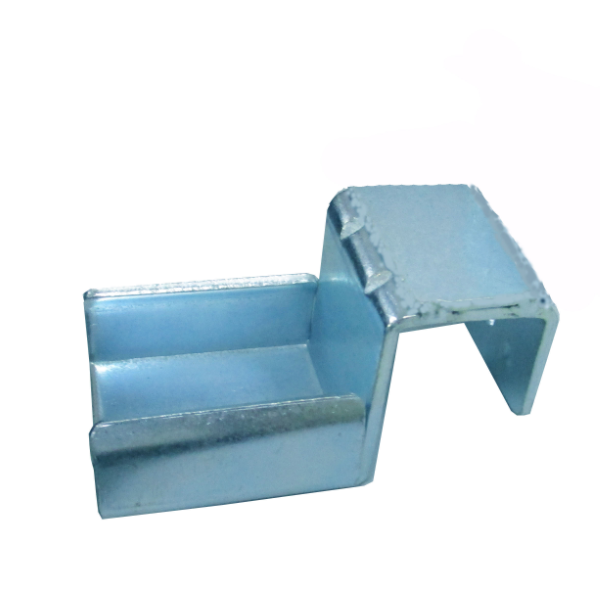

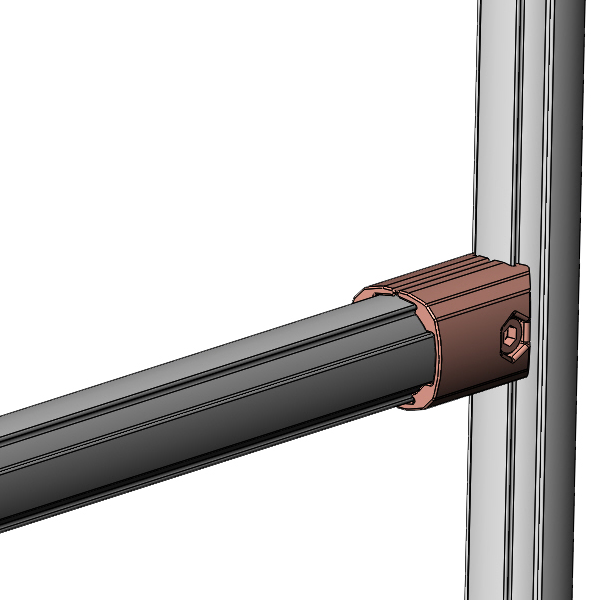

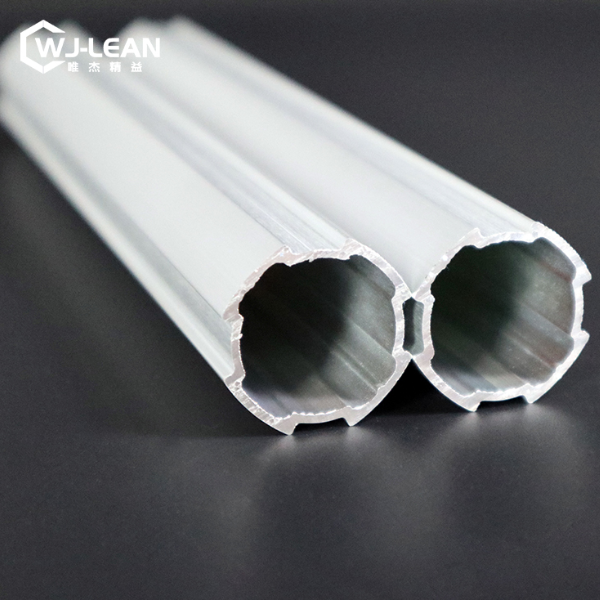

1. WJ-LEAN’s aluminum tube use international standard size, can be used in any international standard parts.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, the surface is smooth without burrs, and the overall system is beautiful and reasonable after assembly.

4.Product diversification design, DIY customized production, can meet the needs of different enterprises.

Application

As the most commonly used accessory in karakuli system, it has convenient and fast characteristics when assembling various worktables and distribution racks. Only one bolt is required at the connection to make simple assembly, and the bolt can be loosened for simple disassembly. The turnover car made of aluminum alloy lean pipe is lighter than the turnover car made of traditional lean pipe. The load capacity will increase, which can save the operator’s strength and improve the work efficiency.

Product Details

| Place of Origin | Guangdong, China |

| Application | Industrial |

| Shape | Square |

| Alloy Or Not | Is Alloy |

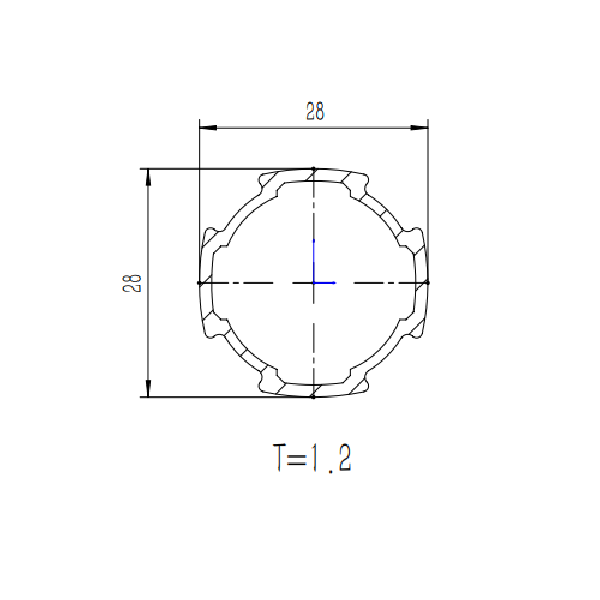

| Model Number | AP-28A-1.2 |

| Brand Name | WJ-LEAN |

| Groove width | 1.2mm |

| Temper | T3-T8 |

| Standard length | 4000mm |

| Weight | 0.382kg/m |

| Material | 6063T5 aluminum alloy |

| Size | 28mm |

| Color | Sliver |

| Packaging & Delivery | |

| Packaging Details | Carton |

| Port | Shenzhen port |

| Supply Ability & Additional Information | |

| Supply Ability | 2000 pcs per day |

| Selling Units | PCS |

| Incoterm | FOB, CFR, CIF, EXW, etc. |

| Payment Type | L/C, T/T, D/P, D/A, etc. |

| Transportation | Ocean |

| Packing | 10 bar/box |

| Certification | ISO 9001 |

| OEM,ODM | Allow |

Structures

Production Equipment

As the Lean products manufacturer, WJ-lean adopts the world’s most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, WJ lean can also handle various customer needs with ease. At present, WJ-lean’s products have been exported to more than 15 countries.

Our Warehouse

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. WJ-lean has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

Product detail pictures:

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for The third generation lean pipe aluminum alloy pipe – WJ-LEAN , The product will supply to all over the world, such as: Rotterdam, The Swiss, Kyrgyzstan, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!